X9 1100 Combine

- John Deere

- Combines X Series Combines

Find Your Nearest Location

Key Features & Specs

- 690 Max engine horsepower

- 5.3 bu/s peak unload rate

- 460-bushel power folding grain tank

- JDLink™ connectivity

- All-new cab

- + Expand All

- - Close All

-

John Deere X9 1100 vs. CLAAS® 8800 – Independent PAMI benchmarking

X9 1100, PAMI storage band and collector

X9 1100, PAMI storage band and collector

Combine capacity, time, and money - what are they worth to you? In late September and early October of 2020, John Deere contracted PAMI (Prairie Agricultral Machinery Insitute) to conduct independent benchmarking of the John Deere X9 1100 Combine versus the CLAAS 8800 Combine. PAMI tested these combines in tough wheat and canola conditions in Western Canada, and what they found was impressive. Read the full PAMI reports at www.pami.ca/publications.

Capacity

In 102 bu/acre wheat, PAMI found the X9 1100 Combine had a 28 percent capacity advantage over the CLAAS 8800 at a 1 percent total loss threshold (figure 10 of the PAMI report). Considering a farm with 8,000 acres of wheat, here is a breakdown of how a John Deere X9 Combine would compare to a CLAAS 8800 when harvesting wheat at 1 percent loss:

Harvesting wheat at 1 percent loss

X9 1100

CLAAS 8800

X9 1100

advantageTotal throughput (tonnes/hr)

115

90

25

More tonnes/hr

Combine capacity (bu/hr)

2,306

1,801

505

More bu/hr

Productivity (acres/hr)

18

14

4

More acres/hr

Productivity (acres/14-hour day)

253

198

55

More acres/day

Machine depreciation (dollars/acre)

$19.75

$25.28

$5.53

Savings per acre

Operator cost at $30/hr (dollars/acre)

$18,960

$24,270

$0.66

Savings per acre

Total fleet value depreciation

$157,997

$202,238

$44,241

In depreciation saved

Days of harvest needed (14-hour days) with two machines

22.57

28.89

6.3

Fewer harvest days

Time and money

With a John Deere X9 Combine, you can simply harvest more acres in less time and with less grain loss. In fact, as you can calculate from the PAMI testing results, the X9 Combine can save you 6.3 total harvest days when compared to the CLAAS 8800 in a two-machine harvest scenario. This is essentially a week of time saved in the field with your combines. A lot can happen in one week, including rain storms that reduce your wheat’s test weight or snow storms that can prolong your harvest and make for very difficult harvesting conditions in the future. An X9 combine helps you manage this risk by enabling a faster and cost-saving wheat harvest, so you can get into other crops such as canola and pulses much earlier.

In addition to getting your crop out of the field faster, an X9 Combine also directly saves you money by requiring less time to do the same amount of work. The X9 can save you $0.66 per acre in operator time and $5.53 per acre in depreciation savings, for a total savings of up to $6.19 per acre when running at 1 percent loss.

Everything discussed until this point has been at a 1 percent loss rate. Let’s say storms are in the forecast and you need to get your wheat crop off the field as fast as possible. An X9 Combine is up to that task as well. When PAMI tested both machines to a power limit condition (figure 10 of the PAMI wheat report), here’s what they found:

Harvesting wheat at power limit

X9 1100

CLAAS 8800

X9 1100

advantageGrain loss (percent/acre)

2

6

4

Percent less loss per acre

Grain loss value (dollars/acre)

$12.04

$36.11

$24.07

Savings per acre

At power limit, the X9 1100 never exceeded 2 percent loss, and the CLAAS 8800 reached a 6 percent loss rate. When you need to get your crop off the field as fast as possible, the X9 can save you up to $24.07 per acre compared to the CLAAS 8800. Additionally, more available power would not have helped the CLAAS 8800 close this gap, since the 8800’s loss rate was already increasing at a higher rate compared to the X9 1100. If rain or snow is in the forecast or if you are short on time, an X9 Combine can deliver outstanding performance in tough conditions as demonstrated in the results of the PAMI testing.

Canola harvesting

Harvesting canola

X9 1100

CLAAS 8800

X9 1100

advantageTotal throughput (tonnes/hr) at 3 percent loss

63

63

Equal

Tonnes/hr

Total capacity (bu/hr) at 3 percent loss

1,152

1,152

Equal

bu/hr

Maximum throughput achieved (tonnes/hr)

89

73

16

More tonnes/hr

Fuel consumption (gal./100 bu)

1.96

2.38

18

Percent less fuel per bushel

When PAMI tested the machines in canola, both machines performed well in tough conditions. Each machine reached a total throughput of 63 tonnes/hr or 1,152 bu/hr at a 3 percent loss rate. However, the X9 1100 used 18 percent less fuel per bushel harvested than the CLAAS 8800 in these tests. When you consider this on a farm with 4,000 acres of canola, you’d save over 1,227 gal. of fuel or $0.79 per acre. PAMI also mentions that machine noise and distress were limiting factors on how hard the machines could be pushed in these conditions, and the X9 1100 could be ran at a higher throughput (see figure 10 of the PAMI canola report). This again speaks to the performance of X9 Combines when needing to harvest in the toughest conditions.

Summary

More acres in less time and with less cost is what the independent PAMI benchmarking results prove you get when you purchase a John Deere X9 Combine. Reach out to your John Deere dealer to learn more about how the X9 Combine can help you be more successful in your operation.

Assumptions

The examples provided here are based on the yields and conditions where the independent PAMI benchmarking took place. Actual values will vary depending on your conditions, yields, machine count, and operational efficiencies. Here is a summary of the values used:

- All $ amounts are in U.S. dollars

- 8,000 acres of wheat

- 102 bu/acre for wheat yield

- $5.90 per bushel for wheat

- 4000 acres of canola

- 72 bu/acre for canola yield

- $11.60 canola per bushel

- $2.10 per gallon for diesel

- Machine depreciation and total fleet depreciation are based on a $250 per engine hour reduction in value. It should be noted that different rates may be experienced in the market. This rate is for this example only.

- 0.8 field efficiency factor

- One harvest day assumes a 14 engine hour day with a 0.7 separator hour-to-engine hour ratio

CLAAS is a trademark of CLAAS KGaA mbH.

-

Make quick, informed decisions in a combine packed with ready-to-harvest technology

X Series in-cab technology

X Series in-cab technology

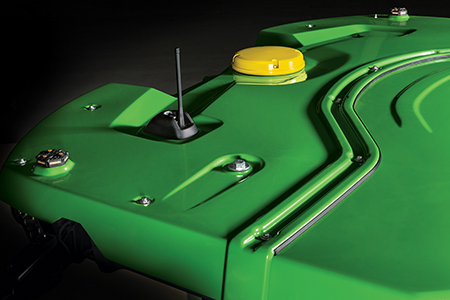

StarFire™ 6000 Integrated Receiver

StarFire™ 6000 Integrated Receiver

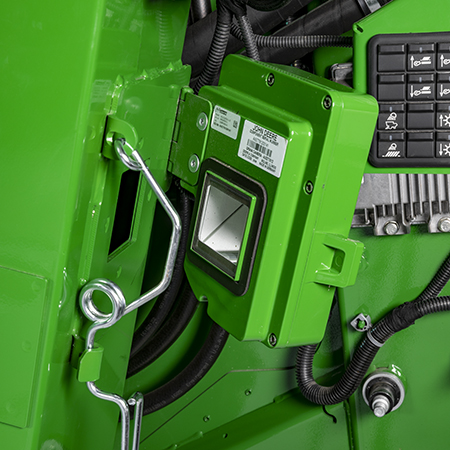

X Series Combine Advisor™ ActiveVision™ tailings camera

X Series Combine Advisor™ ActiveVision™ tailings camera

Make business decisions with the integrated technologies in the X Series. The combine learns on the go to improve your harvest, reduce losses, and leave cleaner grain. You’ll collect more accurate data, improve harvest results with automation, and make more informed decisions by connecting all your machines. What’s even better, the X9 Combines do much of this automatically in the background.

- StarFire™ 6000 Integrated Receiver eliminates all setup, installation, and calibrations – The integrated design is ready to harvest with AutoTrac™ guidance in base. There is no need to verify machine and receiver measurements, as this has been done precisely for you at the factory.

- Improve grain quality and reduce losses with Combine Advisor™ technology package - Automatically adjust the combine’s harvest settings. Cameras on the clean grain and tailings elevator help you make informed decisions on the crop that is flowing up and into the grain tank.

- Automation 4.0 - The combine can unload 100 times or more every day with larger heads, so caution and safety are even more important. Machine Sync connects the grain cart to the combine, letting the combine operator adjust the speed and location of the cart, automating all tractor movement. The grain cart operator can see where all the combines are in the field, as well as which one is closest to full, prioritizing unloading and improving overall logistics. AutoPath™ system maps each planter row and maximizes harvest efficiency by creating your harvest AB lines, keeping the header full during each pass.

- Send data to your home office, dealer, or trusted partners - All X9 Combines come with a 5-year subscription to JDLink™ Connect, which automatically sends yield maps and other harvest data to the Operations Center for later analysis. From your office, JDLink gives you a look at all your machines – where they are, how they’re performing, and what action you can take to improve your harvest.

- Generate, collect, and analyze all your harvest data easier than ever with John Deere Operations Center - Operations Center makes it easier than ever to view, analyze, and compare different map layers and print out reports to make next year’s harvest even more profitable. Plus, you have access to more than 100 connected software tools, and you can easily share your harvest data with your trusted partners to help you make better decisions.

- StarFire™ 6000 Integrated Receiver eliminates all setup, installation, and calibrations – The integrated design is ready to harvest with AutoTrac™ guidance in base. There is no need to verify machine and receiver measurements, as this has been done precisely for you at the factory.

-

Make long harvesting days feel shorter with the most comfortable cab available

X Series cab

X Series cab

Leather seat inside of cab

Leather seat inside of cab

All X9 Combines provide a quiet, comfortable ride with visibility, control, and convenience that are even better than previous John Deere cabs. Choose from three comfort and convenience packages to find a cab that fits you best.

- Leather seat with massage, heating and cooling, electronic controls, and increased swivel (up to 16 degrees, both left and right) – When you sit down in the plush leather seat, the long days and nights won’t seem so long. It’s also quiet enough to take a phone call without worry. You’ll love the convenience of five cup-holders, an accessory rail with an iPad® tablet mount, USB and power ports, and closed storage. Plus, you can easily connect your smartphone to the 16.5-cm (6.5-in.) touchscreen radio to enjoy your favorite playlist or podcast.

- Smooth out 90 percent of vertical movements with ActiveSeat™ suspension – The electric motor responds instantly to the ruts, bumps, and jolts, delivering an unbelievably comfortable ride. While you’re harvesting more acres per hour, you’ll stay refreshed and alert.

- Get unmatched visibility – The 360-degree light-emitting diode (LED) lighting package delivers twice as much illumination as previous designs. Unloading on the go during the day is easier, too. The wide 106-degree unloading auger gives you a straight line of sight to the grain cart, while cameras on the unloading auger, grain tank, and rear of combine help you see into the grain cart, grain tank, and everything behind you.

- Make in-cab adjustments with more programmable features on the CommandARM™ controls – Feeder house tilt, header resume, machine speed, AutoTrac™ guidance, unloading, residue spread widths, and even more features are located on the CommandARM controls using logical, color-coded, and easy-to-read icons that make it a breeze to run the combine or train new operators. You can even program the functions you use most with up to 30 percent more programmable features than any other combine controller.

iPad is a trademark of Apple Inc.

- Leather seat with massage, heating and cooling, electronic controls, and increased swivel (up to 16 degrees, both left and right) – When you sit down in the plush leather seat, the long days and nights won’t seem so long. It’s also quiet enough to take a phone call without worry. You’ll love the convenience of five cup-holders, an accessory rail with an iPad® tablet mount, USB and power ports, and closed storage. Plus, you can easily connect your smartphone to the 16.5-cm (6.5-in.) touchscreen radio to enjoy your favorite playlist or podcast.

-

All-day performance in all crops and conditions with the X9 Combine

X Series harvesting in the early morning and late at night

X Series harvesting in the early morning and late at night

You want the ability to be more productive early in the morning when the crop is tougher and later in the evening as the dew settles. With the X Series, no matter what condition your fields are in, it keeps performing like it’s the middle of the day. More importantly, the combine stretches the length of the harvest window, allowing you to get in the fields sooner and stay later than before, without risking a loss in productivity or grain quality.

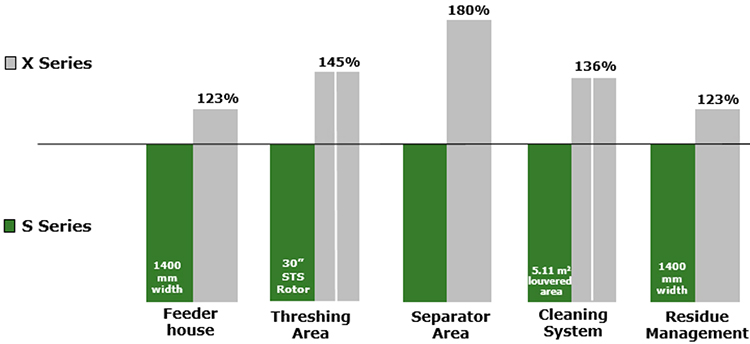

Comparison of features between S-Series and X Series Combines

Comparison of features between S-Series and X Series Combines

- More productivity in the early morning and late afternoon – The feederhouse is 23 percent wider than previous models, allowing it to handle as much as 100 tons/hr of wheat or 253,721.3 L (7200 bu) per hour of high-yielding corn. Increased rotor threshing and separation area improves your ability to harvest in tough conditions. Increased cleaning shoe area improves your grain tank sample, the 23 percent wider residue system can effortlessly chop and spread residue. The result is an X9 Combine that can handle early-morning’s thick wet crop or the highest-yielding parts of your field with less plugging.

- Automated setting adjustments with Combine Advisor™ technology package – Crop conditions change dramatically throughout the day and from field to field, which means you can spend time changing combine settings or you can run an X Series Combine that makes the adjustments for you. Combine Advisor adjusts all five harvesting settings as conditions change, reducing grain loss and improving quality. It automatically compensates for changing conditions like wet straw and dewy conditions, even if you can’t see them.

- Faster crop changeover with improved rotor/fast rpm shift, lighter concaves, and no-tools-required grain tank cleanout – Spend more time harvesting and less time prepping. The rotor and fast gear shift location has moved next to the cab door entrance for quick shifting when changing to different crops. The half-width concaves are lighter, making them easier to handle and remove. Each of the six concaves weigh less than 14 kg (31 lb), and drop-down cradles make it easy to slide the concaves into position. No tools are required to clean out the grain tank, making it easier to quickly remove crop before heading to the next field.

- More productivity in the early morning and late afternoon – The feederhouse is 23 percent wider than previous models, allowing it to handle as much as 100 tons/hr of wheat or 253,721.3 L (7200 bu) per hour of high-yielding corn. Increased rotor threshing and separation area improves your ability to harvest in tough conditions. Increased cleaning shoe area improves your grain tank sample, the 23 percent wider residue system can effortlessly chop and spread residue. The result is an X9 Combine that can handle early-morning’s thick wet crop or the highest-yielding parts of your field with less plugging.

-

More bushels per hour, more acres per day

X Series harvesting corn, wheat, and canola

X Series harvesting corn, wheat, and canola

If you ever wished you could harvest a few more acres per day, the X Series Combines is the right choice for you. More capacity – up to a 70 percent increase on the X9 1100 – means you can cover a lot more ground with improved grain quality and less grain loss.

Crop type S790 X9 1000 X9 1100 Harvesting capacity

(percent above an S790)Tough wheat 100 percent 134 percent 170 percent Canola 100 percent 135 percent 140 percent High-moisture corn 100 percent 130 percent 150 percent Soybeans 100 percent 130 percent 145 percent - Harvest up to 7200 bu per hour in high-yielding corn and 30 acres per hour in wheat – The X Series dual separator with 45 percent more threshing area and 80 percent more separating area than previous models improve performance in the toughest conditions.

- Reduce losses and improve grain tank quality – With 36 percent more cleaning area and 85 percent more air flow than previous models, the Dyna-Flo™ XL cleaning shoe was built to handle the increased capacity from the rotors. The industry’s largest cleaning shoe keeps loss levels low and grain quality high; you’ll really appreciate the difference in tough wheat, canola, and high-moisture corn.

- Harvest up to 7200 bu per hour in high-yielding corn and 30 acres per hour in wheat – The X Series dual separator with 45 percent more threshing area and 80 percent more separating area than previous models improve performance in the toughest conditions.

-

Lower your harvesting costs, raise your expectations

X Series harvesting high-moisture corn

X Series harvesting high-moisture corn

X Series harvesting wheat

X Series harvesting wheat

The X Series helps reduce fuel costs by 20 percent per bushel harvested. Plus, you can count on an improved grain tank sample and better residue spread, which adds up over a harvest season. With this improved design, you can harvest more acres per day with improved fuel consumption.

- 20 percent better fuel efficiency per bushel harvested - Run 14 hours without stopping for fuel and enjoy fuel savings of up to 20 percent or more as measured in gallons per bushel. An updated John Deere engine, belt drive system, and ProDrive™ XL transmission make it possible. The 13.6L (830 cu-in.) John Deere PowerTech™ engine runs at 1900 rpm during harvest and is partnered with an updated driveline layout that reduces parasitic loss to improve fuel economy. The ProDrive XL transmission leverages two efficient motors to improve power transfer at typical harvesting speeds, and when moving to the next field you can travel up to 40 km/h (25 mph) to get back to harvesting.

- 36 percent larger cleaning shoe more efficiently cleans high-yielding and high-foreign-matter crops with less loss and a better grain tank sample - Conditions may change throughout the day but your grain quality won’t. The massive 7-m2 (75-sq ft) Dyna-Flo™ XL cleaning shoe delivers 36 percent more cleaning area to effectively handle thin dry crop, thick wet crop, and everything in between.

- Uniform residue spread up to 15.2 m (50 ft) with the ability to properly size residue from the cab - Size the chaff and spread it where you want it to speed decomposition and improve soil warming – a feature you’ll really appreciate next year in the spring.

- 20 percent better fuel efficiency per bushel harvested - Run 14 hours without stopping for fuel and enjoy fuel savings of up to 20 percent or more as measured in gallons per bushel. An updated John Deere engine, belt drive system, and ProDrive™ XL transmission make it possible. The 13.6L (830 cu-in.) John Deere PowerTech™ engine runs at 1900 rpm during harvest and is partnered with an updated driveline layout that reduces parasitic loss to improve fuel economy. The ProDrive XL transmission leverages two efficient motors to improve power transfer at typical harvesting speeds, and when moving to the next field you can travel up to 40 km/h (25 mph) to get back to harvesting.

-

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Cleaning

| Cleaning fan speed | 570 to 1430 rpm |

| Total cleaning area (louvered) | 6.97 m2 75.02 sq ft |

| Chaffer | 3.13 m2 33.69 sq ft |

| Sieve area | 2.87 m2 30.89 sq ft |

| Front chaffer | 0.97 m2 10.4 sq ft |

Engine

| Engine family | PowerTech |

| Rated speed | 1900 rpm |

| Emission level | Final Tier 4 (FT4) |

| Fuel capacity | 1249.2 L 330 gal. |

| Power boost @ rated speed | 39.5 kW 53 hp |

| Rated power | 450 kW 603 hp |

| Maximum power | 515 kW 690 hp |

| Engine type | John Deere PowerTech PWS 13.6 L 830 cu in. |

Feeding

| Conveyor chain slat type | Four-strand chain with formed steel slats |

| Drive type | Fixed or variable speed |

| Width | 1720 mm 67.7 in. |

| Feed Accelerator, Stone Trap (FAST) | Reverser Modulated feederhouse reverser Eight-wing chevron FAST |

Grain handling

| Grain tank size | 16,200 L 460 bu |

| Unloading rate | 186 L/s 5.3 bu/sec |

| Unloading auger length | 7.9, 8.7, or 9.45 m 26, 28.5, or 31 ft |

Key Specs

| Fuel capacity | 1249.2 L 330 gal. |

| Separating area | 3.6 m2 38.75 sq ft |

| Rotor diameter | 60.1 cm 24 in. |

| Total cleaning area (louvered) | 6.97 m2 75.02 sq ft |

| Concave area | 1.6 m2 17.22 sq ft |

| Unloading rate | 186 L/s 5.3 bu/sec |

| Engine type | John Deere PowerTech™ PSS 13.6 L 830 cu in. |

| Rated power | 450 kW 603 hp |

| Grain tank size | 16,200 L 460 bu |

| Rotor length | 3.51 m 11.5 ft |

Manufacturing location

| Country | United States |

Threshing/ Separating

| Rotor speed range | 300 to 1300 rpm |

| Separator type | Dual rotor |

| Rotor diameter | 60.1 cm 24 in. |

| Separating area | 3.6 m2 38.75 sq ft |

| Concave area | 1.6 m2 17.22 sq ft |

| Rotor length | 3.51 m 11.5 ft |

| Discharge grate area | 0.4508 m2 4.85 sq ft |

Additional information

| Date collected | 15 June 2020 |