Q820M QuikTrak™ Stand-On Mower

- John Deere

- QuikTrak Stand-On Mowers

Find Your Nearest Location

Key Features & Specs

- 23.5-hp (17.5-kW)

- 48”, 54”, and 60” 7Iron™ PRO decks

- Mow up to 10 mph

- Warranty: 36 months or 1200 hours, whichever comes first; First 24 months, no hour limitation**

- Features 12-gallon fuel tank, 24” foot platform

- HP* 23.5-hp (17.5-kW)

- Deck 7Iron™ PRO

- Fuel Options Gas

- Deck Size 48", 54", and 60"

- + Expand All

- - Close All

-

Exclusive three-year, bumper-to-bumper warranty is standard with a QuikTrak™ Mower

Q800 QuikTrak Mowers

Q800 QuikTrak Mowers

Hassle-free three-year warranties

The E and M Series QuikTrak mowers have a 1200-hour or 36-month, whichever comes first, bumper-to-bumper warranty. The R Series mowers have a 1500-hour or 36-month, whichever comes first, warranty. All QuikTrak Mowers also have an unlimited hour 24-month warranty. The warranty is hassle free, with John Deere covering the complete machine.

The QuikTrak warranties are also aligned with John Deere’s commercial walk-behind and Z900 ZTrak Mowers so you can roll your entire fleet on one contract, with one warranty duration, and one payment schedule.

-

Commercial-quality engine is reliable and provides excellent performance and life

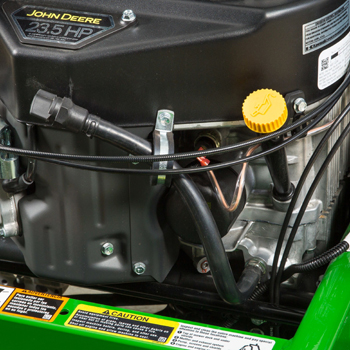

Engine (Q850M shown)

Engine (Q850M shown)

Heavy-duty, dual-stage air cleaner (Q850M shown)

Heavy-duty, dual-stage air cleaner (Q850M shown)

Commercial-quality V-twin air-cooled engines power the QuikTrak™ Mowers:

- FX730V 23.5 hp (17.5 kW) gross at 3600 rpm (Q820M)

- FX850V 27 hp (20.1 kW) gross at 3600 rpm (Q850M and Q850R)

Both engines feature:

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

- Better fuel efficiency

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Filtered oil reduces risk of contamination for increased engine life

- V-twin design

- Fast starts

- Smooth operation

- Vertical shaft for efficient transfer of power to the transmission

- Standard dual-element, canister-type, dry replaceable, heavy-duty air cleaner with secondary safety element

- Fuel pump for consistent and reliable fuel supply to the carburetor

- Air-cooled engine design for minimum maintenance and maximum reliability

- Standard cleanout ports for easy access to remove debris collecting in cooling fins

- Aluminum cylinder block

- Effectively dissipates heat

- Lightweight and strong construction

- Extends engine life due to elimination of debilitating engine temperatures

Engine oil-fill/check tube, drain hose, oil filter, and cleanout port

Engine oil-fill/check tube, drain hose, oil filter, and cleanout port

The engine is equipped with a replaceable oil filter for longer engine life.

Engine oil fill/check tube, oil filter, and oil drain hose are located on the front of the engine where they are easy to access.

Mow all day with 12 U.S. gal. (45.3L) of fuel storage

Dual-fuel tanks (shown on Q850R)

Dual-fuel tanks (shown on Q850R)

Dual 6-U.S. gal. (22.7-L) fuel tanks provide 12 U.S. gal. (45.3 L) of fuel storage that eliminates mid-day refueling and the hassle of gas cans.

The fuel tanks are:

- Designed to complement the mower’s styling

- Molded with a low and narrow profile to avoid contact with overhanging obstacles like mailboxes

- Placed so the operator has visibility of the rear tires and mower deck

- Located low to improve stability

- Balanced so the center of gravity doesn’t shift with the fuel level

- Equipped with wide openings that simplify fueling and reduce spills

- Fitted with sealed fuel caps that reduce vapor loss and a tether that prevent misplacing the cap

A fuel gauge on the display panel keeps the operator informed about the amount of fuel remaining in the tank.

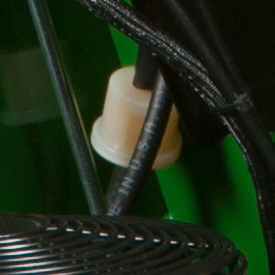

Fuel filter used on carbureted models

Fuel filter used on carbureted models

A high-quality fuel filter is located where it easy to access and change.

-

Frame is compact and durable for productivity and long life

M and R Series QuikTrak™ Mower frame

M and R Series QuikTrak™ Mower frame

Q820M QuikTrak frame

Q820M QuikTrak frame

Built upon a strong foundation

The M and R Series QuikTrak Mowers are built upon a fully-welded frame constructed from 1.5-in. x 3-in. (3.8-cm x 7.6-cm) 7-gauge, 0.18-in. (4.6-mm) tubular steel for added strength and durability.

Designed to cross the curb

Q820M QuikTrak Mower traversing a curb

Q820M QuikTrak Mower traversing a curb

QuikTrak mowers are frequently used on properties with concrete street curbs. The ability to traverse curbs boosts productivity by reducing transit time. The M and R Series QuikTrak Mowers include the following features that allow for efficient and damage-free curb crossings:

- Angled foot platform geometry that clears a 6-in. (15-cm) curb

- Tall rear tires that can climb a curb with confidence

- Mower deck lift system with elevated transport position

- Center-rear and three front anti-scalp wheels that reduce deck scraping

Large tires provide a smoother ride and increased traction:

- 13x5-6 (M Series) or 13x6.5-6 (R Series) flat-free front caster wheels

- 22x10.5-12 rear pneumatic tires on M Series with 48-in. (122-cm) mower decks

- 22x12-12 rear pneumatic tires on M Series with 54-in. (137-cm) or 60-in. (152-cm) mower decks

- 24x12-12 rear pneumatic tires on R Series

-

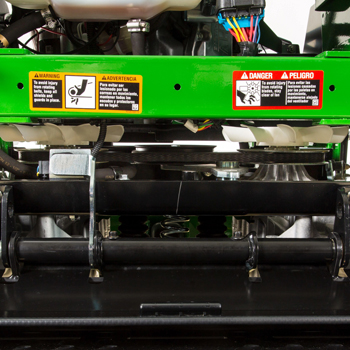

Durability and mowing performance from 7Iron™ PRO Mower Decks forged from a single piece of steel

48-in. (122-cm) 7Iron PRO Mower Deck

48-in. (122-cm) 7Iron PRO Mower Deck

54-in. (137-cm) 7Iron PRO Mower Deck

54-in. (137-cm) 7Iron PRO Mower Deck

60-in. (152-cm) 7Iron PRO Mower Deck

60-in. (152-cm) 7Iron PRO Mower Deck

Overview

M and R Series QuikTrak™ Mowers have 7Iron PRO Mower Decks that are built to last, while delivering a high-quality cut in diverse conditions.

Mower deck

Q820M

Q850M

Q850R

Q865R EFI

48-in. (122-cm) 7Iron PRO

x

54-in. (137-cm) 7Iron PRO

x

x

x

60-in. (152-cm) 7Iron PRO

x

x

x

x

Built to last

Rectangular leading-edge reinforcement

Rectangular leading-edge reinforcement

Trim-edge bumper

Trim-edge bumper

The mower deck shell is forged from a single sheet of 7-gauge, 0.179-in. (4.6-mm) steel. There are fewer welds to wear or break than shells built from multiple fabrications.

Rectangular leading-edge reinforcement and rounded corners help distribute impact stress to reduce potential for damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

The trim edge of the deck is equipped with a bumper that provides extra abrasion resistance to protect the machine and the property.

Three 1-in. (2.5-cm) cold-forged spindle shafts are heat-treated for strength and supported by ball bearings. Deep spindle pockets keep the blades aligned, even after years of tough operation. The ribbed spindle housings are made of aluminum and have an 8-in. (20-cm) base for added strength and heat dissipation.

Exceptional mowing results

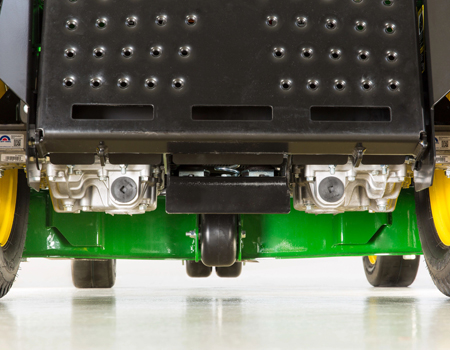

Underside of 48-in. (122-cm) 7Iron PRO Mower Deck

Underside of 48-in. (122-cm) 7Iron PRO Mower Deck

Minimal welds provide a smoother underside with fewer sharp corners for reduced material buildup.

Higher blade-tip speed than many competitors - approximately 18,000 fpm (5,486 m/min) for more blade cuts per inch mowed.

A deep-deck design of 5.5 in. (14 cm) delivers excellent airflow so material can be processed quickly and efficiently.

The front edge is raised above the blade plane to allow even cutting of tall grass.

The wider and higher discharge opening provides even clipping dispersal for an excellent finished appearance in all conditions.

Blade overlap is 1.6 in. (40.6 mm) to reduce striping between blades.

Dual-captured front-corner, front-center, and rear-center anti-scalp wheels provide deck flotation over even the toughest terrain.

Simple to maintain and clean

Q820M with engine guard folded open

Q820M with engine guard folded open

Spindle covers that allow for cleaning while installed

Spindle covers that allow for cleaning while installed

Deck level adjustment

Deck level adjustment

A folding engine guard provides access to the mower deck drives for cleaning and maintenance.

Spindle covers allow for cleaning while installed and can be removed without tools for maintenance. Spindle grease fittings are accessible through the top of the spindle cover.

Adjustment screws at each lift point are used to level the mower deck side-to-side and set the rake angle. The mower deck is fully supported throughout the leveling process, enabling predictable adjustments and precise height measurements.

-

Spacious operator platform gives operators room to move

Q850M operator station

Q850M operator station

Q850R operator station

Q850R operator station

Overview

M and R Series QuikTrak™ Mowers have a spacious operator platform designed to keep operators comfortable and improve stability, while providing storage.

Room to move

Q850R QuikTrak Mower

Q850R QuikTrak Mower

Q850R QuikTrak Mower

Q850R QuikTrak Mower

Moving is essential for operator ergonomics, so the M and R Series QuikTrak Mowers are equipped with a 24-in. (61-cm) wide foot platform that gives the operator room to vary their stance. The fender-mounted foot holds on R Series Mowers enable an even wider range of stance options.

Smooths out the bumps

The platform is spring loaded to keep bumps from jarring the operator. Large tires help isolate the operator from rough ground as well. R Series Mowers include a rubber mat on the foot platform.

Keeps the operator at center of control

Q850M QuikTrak Mower

Q850M QuikTrak Mower

M Series leaning pad

M Series leaning pad

The forward pitch of the new M and R Series leaning pad centers the operator’s core over the vehicles center of rotation. This location has the least centrifugal force, keeping the operator stable and in control. The leaning pad is padded for comfort and bolstered to provide side support to the operator while traversing uneven terrain and during end-of-pass turns. The leaning pad on R Series includes extra bolstering and a color accent.

Traction when you need it

The wide foot platform gives the operator the freedom to shift their weight from side-to-side on uneven terrain. Similarly, the forward-pitched leaning pad allows the operator to lean forward to increase stability or lean rearward to increase traction.

A place for tools and trash

Mesh storage bin

Mesh storage bin

A versatile mesh storage bin is within the operator’s reach and can be used for holding refreshments, tools, or trash.

-

Simple to clean and maintain

Q850R QuikTrak™ Mower

Q850R QuikTrak™ Mower

Q820M with engine guard folded open

Q820M with engine guard folded open

Overview

The M and R Series QuikTrak Mowers are designed to speed maintenance and cleaning so the mower can get back to work.

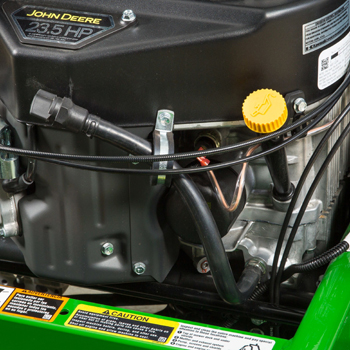

Folding engine guard provides access for engine maintenance

Heavy-duty dual-element canister-type air cleaner

Heavy-duty dual-element canister-type air cleaner

Engine oil fill/check tube, oil drain hose, oil filter, and cleanout port

Engine oil fill/check tube, oil drain hose, oil filter, and cleanout port

All service and maintenance points are within easy reach.

Canister-type heavy-duty air cleaner is easy to reach and easy to service:

- Air cleaner has two filter elements; a large outer filter and a smaller inner safety filter.

- Both filters are easy to access and easy to change.

Engine oil service points are grouped together in an easy-to-reach location:

- Reduces the time required to check and/or change the oil and filter.

Simple to clean and maintain

Q820M with leaning pad removed

Q820M with leaning pad removed

Q820M with leaning pad and service panels removed

Q820M with leaning pad and service panels removed

Transaxle belt drive

Transaxle belt drive

A removable leaning pad, removeable rear service panel, and folding rear service panel provide access to key components for maintenance and cleaning.

A secure location is provided to protect the battery. Only the leaning pad needs to be removed for access.

Access to check and service the hydrostatic transaxles and drive belts are readily available at the rear of the machine.

Transmission bypass valves are located on the hydrostatic pumps to enable moving the vehicle without the engine running.

A periodic service chart is provided for convenience in keeping up on required service.

Mower deck

Mower deck spindle cover

Mower deck spindle cover

Mower deck drive with spindle cover removed

Mower deck drive with spindle cover removed

Deck level adjustment

Deck level adjustment

Spindle covers allow for cleaning while installed and can be removed without tools for maintenance. Opening the engine guard also provides access to mower deck drives.

Adjustment screws on each lift point are used to level the mower deck side-to-side and set the rake angle. The mower deck is fully supported throughout the leveling process, enabling predictable adjustments and precise height measurements.

Tie-down points

Front tie-down points

Front tie-down points

Rear tie-down points

Rear tie-down points

Four tie-down locations, two at the front and two at the rear, are provided for safely towing or anchoring the vehicle.

Quick response (QR) codes link to owner information web pages

QR (quick response) code label

QR (quick response) code label

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on the rear of the mower, to the right of the leaning pad. The owner information web pages include links to:

- Safety and how-to videos Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets Attachments

- Warranty statements

-

Compact design for easy hauling and excellent maneuverability

Overhead view of Q820M showing compact design

Overhead view of Q820M showing compact design

Side view of Q820M showing compact design

Side view of Q820M showing compact design

From the operator's platform to the mower deck, John Deere QuikTrak™ Mowers have a compact and functional design:

- The compact design allows the QuikTrak to operate in tighter areas that a larger machine cannot. Often, this means the area can be mowed with a QuikTrak so it is not necessary to switch to a walk-behind mower, reducing the time on site.

- With the compact design of QuikTrak Mowers, less space is required on a truck or trailer - which can mean there is room for an extra mower, resulting in less time on property, saving time and money.

Whether mowing hills or on level terrain, trimming or mowing straight-away, the operator of a John Deere QuikTrak is able to affect the performance of the machine with their body:

- The compact design of the QuikTrak allows the operator to use their body to help control the machine

- 24-in. (61-cm) wide foot platform gives the operator the freedom to shift their weight from side-to-side as needed on uneven terrain.

- Fender-mounted foot holds on R Series Mowers enable an even wider range of stance options.

- A forward pitched leaning pad and a deep foot platform allow the operator to lean forward to increase stability or lean rearward to increase traction.

- Faster ground speeds get work done quicker.

- Better traction on slopes gives more control and increased productivity. Superior stability gives more control and confidence when mowing hillsides.

- Better visibility allows more-timely operator reaction to the terrain and obstructions.

- Minimal operator-station obstruction allows safe and fast exits for clearing mower-path obstacles.

- Compact design takes less space for mowing tighter areas and may allow room for an extra machine when hauling to the worksite.

-

Integrated transaxles have few potential leak points

Integrated transaxles

Integrated transaxles

The M and R Series QuikTrak™ Mowers use Tuff Torq TZT13 Integrated Transaxles, the same transaxles used on the Z900 ZTrak™ Mowers. The integrated transaxles:

- Include 0.79-cu in. (13-cc) unitized hydraulic pumps combined with 13-cu in. (213-cc) commercial-grade, heavy-duty wheel motors

- Have less potential leak points than separate pump and motor designs

- Enable tall 22- and 24-in. (56- and 61-cm) pneumatic or Tweel drive tires that increase ground speeds and productivity

- Include an internal park brake that need less frequent adjustments than tire-paw designs

- Exceptional cooling in high-load conditions

- Easy-to-check level and refill hydraulic oil

Tuff Torq is a trademark of Kanzaki Kokyukoki Mfg. Co., Ltd.

-

Safety features are built-in to protect the operator and bystanders

Operator Controls

Operator Controls

Mower discharge deflector

Mower discharge deflector

Key safety features of QuikTrak™ Mowers include:

- Start circuit requirements

- Park brake engaged

- Power take-off (PTO) disengaged

- Control levers in neutral

- Ignition key used to start the engine

- A high-quality polyethylene mower-discharge deflector

- Deflects if it strikes a solid obstruction, causing less damage

- Returns to its original shape and function

- Operator station designed to allow fast exit

- Easy to remove and replace shields

- Stationary handles on either side of the traction controls for operator security

- Control levers return to neutral when released

Mower deck safety certification

QuikTrak mower decks are evaluated by the manufacturer (John Deere Turf Care) and conform to American National Standards Institute (ANSI) B71.4 2017 safety certification specifications for commercial turf care equipment.

Optional LED strobe light attachment

Strobe lights

Strobe lights

The optional LED strobe light attachment increases visibility of the QuikTrak mowers to motorists. The kit includes two lights providing visibility in all directions.

-

Get operators up to speed with user-friendly controls

QuikTrak™ Mower (Q850R shown)

QuikTrak™ Mower (Q850R shown)

Control console (Q850M shown)

Control console (Q850M shown)

Overview

The color coded and logically placed controls on M and R Series QuikTrak Mowers are designed to get new operators up to speed quickly. A display panel assists in operating the mower and alerts operators of problems, to reduce downtime and repair costs. The key, choke (carbureted models only), throttle, and power take-off (PTO) switch are located at the operator’s fingertips.

Precise drive controls

Ground speed and direction are easily controlled by moving the two hand-lever hydrostatic drive controls forward or reverse.

- Up to 10 mph (16.1 km/h) forward and 5 mph (8.0 km/h) reverse on M Series Mowers.

- Up to 12 mph (19.3 km/h) forward and 6 mph (9.7 km/h) reverse on R Series Mowers.

Front and rear stationary reference bars stabilize the operator’s hands, which maintains precise control as the mower changes speed or direction. The bars also reduce fatigue from control lever operation.

Control levers return to neutral automatically, and a positive neutral-lock holds the control levers in neutral when the park brake is engaged.

Display panel

Display panel

Display panel

The M and R Series QuikTrak Mowers are equipped with a display panel that assists in operating the mower, alerts of problems to reduce downtime and repair costs, and provides on-board diagnostics to speed troubleshooting. The display panel includes:

- Hour meter

- Fuel level

- Engine speed

- System voltage

- Low engine oil-pressure indicator

- Starting interlock indicators for PTO, operator presence, and park brake

- Bright caution and stop indicators to capture the operator's attention

The diagnostics mode provides error codes, system voltage, and circuit continuity tests that can report switch functionality and circuit continuity in seconds without tools.

Park Brake

Park brake lever

Park brake lever

A park brake is provided for parking the vehicle and for transport. It must be engaged to start the machine and should be engaged whenever the machine is not being used. On M and R Series QuikTrak Mowers, the park brake is built into the transaxles, which reduces the effort required to engage the brake.

Height-of-cut adjustment

Height-of-cut adjustment

Height-of-cut adjustment

An easy-to-use height-of-cut system allows the operator to see and adjust the height-of-cut setting from the operator station.

-

Michelin® X® Tweel® Turf rear tire solution for QuikTrak™ R Series Mowers eliminates downtime

Tweel rear tire on QuikTrak Mower

Tweel rear tire on QuikTrak Mower

John Deere leads the commercial zero-turn mower industry with use of the Michelin X Tweel Turf technology for the QuikTrak Mowers:

- 22x11N12 as an ordering option for QuikTrak Q820M and Q850M Mowers.

- 24x12N12 as an ordering for QuikTrak Q850R and Q865R EFI Mowers.

Michelin is a world leader in tire manufacturing and technology. This airless radial tire solution is an industry first for John Deere, which provides an additional advantage to John Deere operators.

Advantages of the Michelin X Tweel Turf include:- Mowing performance is improved.

- Rutting is reduced because the Michelin X Tweel Turf has more support across the surface for improved flotation and better ground contact.

- Unique energy transfer within the poly-resin spokes reduces the bounce associated with pneumatic tires.

- Excellent curb climbing is possible due to the Michelin X Tweel Turf construction and flexibility.

- More consistent cut quality is achieved because inconsistent tire pressure is eliminated.

- Uptime is improved.

- The exclusive technology eliminates downtime and associated cost due to flat or damaged tires.

- Punctures and sidewall damage no longer result in downtime.

- Cost of operation is reduced.

- Cost of repairs and maintenance is reduced. One single unit replaces the current tire, wheel, and valve assembly. There is no need for complex tire-mounting equipment.

- No need to spend time checking and optimizing tire pressure.

- The need to purchase and stock plug kits and spare tires is eliminated, particularly for professional landscape contractors and government agencies who normally stock them.

- The tire tread will last up to three times longer than current pneumatic tires because automotive-grade rubber is used for the tread.

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Heavy-duty construction provides the ultimate in performance and reliable operation:

- High-strength, poly-resin spokes carry the load.

- Four-hole, heavy-duty steel hub for durability.

- Deep, open-tread design provides excellent cleaning and traction.

- Zero degree, high-tensile, proprietary carcass provides great lateral stiffness while resisting damage from impact and penetration.

Michelin, X, and Tweel are trademarks of Compagnie Générale des Etablissements Michelin SCA.

Blades

| Blade tip speed | Approximately 18,000 fpm 5486 m/min |

| Thickness | 0.25 in. 0.64 cm |

| Number | Three |

Brakes

| Park brake | Internal wet disk |

| Park brake actuation | Hand lever |

| Dynamic braking | Dual hand-controlled levers |

Buyer's note

| Warranty | 36 months or 1200 hours, whichever comes first. First 24 months, no hour limitation. |

Dimensions

| Width | With chute down, 62, 68, 74 in. 157, 173, 188 cm |

| Weight | 1045 lb 474 (48 in.) 1070 lb 485 kg (54 in.) 1095 lb 497 kg (60 in.) |

| Height | 48 in. 122 cm |

| Length | Foot platform up, 67.25 in. 171 cm Foot platform down, 72 in. 183 cm |

Drivetrain

| Speed and direction control | Twin hand-controlled levers |

| Hydraulic pumps | 0.79 cu in. 13 cc |

| Filter | Two internal and replaceable |

| Travel speed | Speed range 0-10 mph 0-16.1 km/h Forward Infinite, 0-10 mph Infinite, 0-16.1 km/h Reverse Infinite, 0-5 mph Infinite, 0-8.0 km/h |

| Transmission | Tuff Torq TZT13 IHT |

| Wheel motors | 13 cu in. 213 cc |

| Hydraulic capacity | 6.0 U.S qt 5.7 L |

| Hydraulic oil cooler | Two 8.5 in. (22 cm) fans |

Electrical system

| Operator presence starting system | Yes |

| Hour meter | Display panel including hour meter, fuel level, engine speed, system voltage, low engine oil pressure indicator, starting interlock indicators (PTO, operator presence, park brake), caution warning, stop warning, and on-board diagnostics |

| Cold cranking amp | 300 CCA |

| Charge system | At 3,600 rpm 20A |

| Battery voltage | 12 V |

Engine

| Oil filter | Full flow, replaceable |

| Air cleaner | Heavy-duty canister type with safety element |

| Cooling | Forced air, with integrated clean out ports |

| Manufacturer/Model | FX730V |

| Cylinders | Two, V-twin |

| Crankcase capacity | With filter, 2.2 qt 2.1 L |

| Power | Gross at 3,600 rpm: 23.5 hp 17.5 kW |

| Lubrication | Full pressure |

| Displacement | 44.3 cu in. 726 cc |

Fuel system

| Fuel tank switch/shut-off valve | No |

| Fuel type | Gasoline |

| Fuel tank capacity | 12 U.S. gal. 45.3 L |

Key Specs

| Mower deck size | 48-in. (122-cm) 7Iron™ PRO side-discharge 54-in. (137-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) 7Iron™ PRO side-discharge |

| Speed range | 0-10 mph 0-16.1 km/h |

| Fuel tank capacity | 12 U.S. gal. 45.3 L |

| Engine power | Gross at 3,600 rpm: 23.5 hp 17.5 kW |

| Caster wheels | 13x5-6 |

| Transmission | Tuff Torq TZT13 IHT |

| Warranty | 36 months or 1200 hours, whichever comes first. First 24 months, no hour limitation. |

| Drive wheels | 22x10-12 pneumatic (48 in.) 22x12-12 pneumatic (54 in., 60 in.) 22x11N12 Tweel |

| Engine Manufacturer/model | FX730V |

| Blade tip speed | Approximately 18,000 fpm 5486 m/min |

Mower decks

| Size | 48-in. (122-cm) 7Iron™ PRO side-discharge 54-in. (137-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) 7Iron™ PRO side-discharge |

| Deck thickness | 7 gauge 0.180 in. 4.6 mm |

| Height-of-cut range | Increments 0.25 in. 0.64 cm 1.5-5 in. 3.8-12.7 cm |

| Cutting width | 48-in. (122-cm) 7Iron™ PRO side-discharge 54-in. (137-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) 7Iron™ PRO side-discharge |

| Deck construction | 7-Iron™ PRO: one-piece forged steel |

| Discharge | Side |

PTO

| Drive | V-belt |

| Type | Electro-magnetic with brake, 125 lb-ft 169 Nm (48 in.) Electro-magnetic with brake, 200 lb-ft 271 Nm (54 in., 60in.) |

Tires

| Load rating | 4 PR |

| Drive wheels | 22x10-12 pneumatic (48 in.) 22x12-12 pneumatic (54 in., 60 in.) 22x11N12 Tweel |

Wheels

| Caster wheels | 13x5-6 |

| Caster wheel type | Flat free |

| Front anti-scalp rollers | RH, center, LH |

Additional information

| Date collected | 28-Aug-2023 |