8345RT Tractor

- John Deere

- Row Crop Tractors 8 Series Row-Crop Tractors

Find Your Nearest Location

Key Features & Specs

- 345 Engine hp

- John Deere PowerTech™ 9.0L PSS

- Choice of e23™ PowerShift, or Infinitely Variable Transmission (IVT™)

- New cab suspension system and CommandView™ III cab and Generation 4 CommandCenter™

- Engine HP 345

- Wheel/Track 2-Track

- Suspension AirCushion Suspension

- Hydraulics Closed-center, pressure and flow compensated with 4 standard SCV (5 and 6 available)

- Cabs New cab suspension system; CommandView™ III

- Transmission Options AutoPowr™ IVT™; available e23™ PowerShift with Efficiency Manager

- + Expand All

- - Close All

-

Hydraulic pump options to meet varying flow requirements

All 8R and 8RT Series Tractors come standard with an 85-cc displacement integrated hydraulic pump. This pump provides 227.1 L/min (60 gpm) of hydraulic flow.

A dual-pump option, featuring 85-cc and 35-cc displacement hydraulic pumps, is available for all 8R wheel models. The dual-pump system provides a hydraulic flow of 321 L/min (85 gpm), ideal for running at lower engine speeds.

SCV flow (approximate)

Engine rpm

Pump flow (85-cm3 pump) L/min (gpm)

High pump flow (85-cm3 pump + 35-cm3 optional pump) L/min (gpm)

800

86 (23)

122 (32)

1500

162 (43)

229 (61)

1700

184 (49)

260 (69)

1900

206 (54)

290 (77)

2100

227 (60)

321 (85)

Operating the tractor at reduced engine rpm contributes to a quieter cab, reduced fuel usage, and maintains the vacuum while turning and raising the planter on end rows. At 1500 erpm with a 321 L/min (85 gpm) system there will be an available flow of 229 L/min (61 gpm). This is an improvement over an available 162 L/min (43-gpm) flow when operating with a 227 L/min (60 gpm) system at 1500 erpm.

The maximum flow through one selective control valve (SCV) with a standard coupler is 132 L/min (35 gpm). A 19.1-mm (3/4-in.) high-flow coupler allows for a maximum flow rate out of one SCV of 153 L/min (40.5 gpm).

The hydraulic system is a closed-center, power-on-demand system using a load-sensing pressure-flow compensated axial piston pump with full-flow charge and flow prioritization for steering and brakes.

The pump outlet pressure available on demand can range from 3000 kPa (435 psi) for track models and 4000 kPa (580 psi) for wheel models at low standby to 20,400 kPa (2958 psi) at high standby.

Hydraulic pump options:

- 85-cc displacement, 227-L/min (60-gpm) hydraulic pump

- NOTE: Standard on all 8R models.

- 85-cc and 35-cc dual pump option, 321-L/min (85-gpm)

- NOTE: Compatible with 2014 Final Tier 4 (FT4) and newer 8R Wheel Tractors only.

- 85-cc displacement, 227-L/min (60-gpm) hydraulic pump

-

Lighting packages provide 360 degrees of coverage for maximum productivity

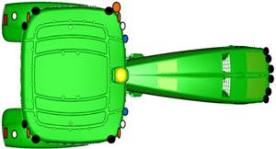

Premium lights

Premium lights

The 7R, 8R, and 8RT Series Tractors feature two lighting package options:

- Standard

- Premium

The cab lighting pattern provides 330 degrees of coverage while the hood lighting provides the remaining 30 degrees for completely programmable 360-degree, stadium-style lighting. This ensures there are no dead zones or lighting adjustments needed. The lighting configurations are available to match various applications and ensure maximum around-the-clock productivity.

Bulb housings are large, allowing for optimum total lumens and available light. The standard lighting packages use 65-W halogen bulbs, whereas the premium lighting package uses light-emitting diode (LED) lights. In the premium lighting package, these tractors take advantage of the high-performing and efficient LED technology.The low- and high-beam driving/work lights are adjustable. Please refer to the electrical section in the operator’s manual for complete details on adjusting lights.

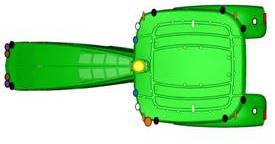

7R/8R/8RT lighting

7R/8R/8RT lighting

Yellow circles

- All lighting packages: 65-W halogen: road low beam

Red circles

- Standard: 65-W halogen

- Premium: LED

Blue circles

- Standard: 65-W halogen; field and road high beams

- Premium: LED

Orange circles

- Standard: blank

- Premium: LED

Adjustable high-beam driving light/work light

License plate bracket with light

Rotary beacon

Fixed halogen light

Adjustable low- beam driving light/work light

Fixed amber light

Adjustable halogen light

Adjustable mid-body halogen light

Fixed high-intensity discharge (HID) light

Adjustable HID light

Mid-body hazard, turn, and width indicating light

Amber turn and brake light

Standard lighting

Standard lighting (8R)

Standard lighting (8R)

Standard lighting (7R)

Standard lighting (7R)

Six front grill-mounted lights:

- Two 65-W low-beam driving/work lights (mid grill screen)

- Two 65-W high-beam driving/work lights (top of grill screen, hood mounted)

- Two front corner-facing halogen work lights (top of grill screen, hood mounted)

10 cab roof-mounted lights:

- Two rear-facing 65-W floodlights

- Four side-facing 65-W floodlights

- Four corner-facing amber lights

Other lights:

- Two rear fender-mounted floodlights

- Two rear turn signal and brake/tail lights (fender mounted)

- Two folding-extremity lights

Plus these lights:

- Two adjustable front roof 65-W halogen floodlights

- Two front belt-line floodlights

- Rotary beacon light

Premium lighting

Eight front grill-mounted lights:

- Two 65-W low-beam halogen driving/work lights (mid grill screen)

- Two LED high-beam driving/work lights (top of grill screen, hood mounted)

- Two front corner-facing LED work lights (top of grill screen, hood mounted)

- Two front-facing LED working lights (top of grill screen, hood mounted, inner position on the sides)

12 cab roof-mounted lights:

- Four side-facing LED lights

- Four corner-facing amber lights

- Two rear-facing LED lights

- Two adjustable front roof LED lights

Other lights:

- Two rear fender-mounted LED lights

- Two rear turn signal and brake lights (fender mounted)

- Two folding-extremity lights

- Two front belt-line LED floodlights

- Rotary beacon light

The premium lighting package replaces all previous halogen and HID lights with LED lights. The only lights that are not LED are the low-beam driving lights, they remain halogen. This allows each LED light to work at a lower temperature and no one light works harder than any other. The uniformity in LED coverage allows only one type of light output surrounding the tractor.

The lighting pattern in the premium package provides industry-leading performance in nighttime visibility. LED bulbs provide maximum brightness and a true color output for excellent field definition that is easy on the operator's eyes.

The LED lights provide 40 percent greater coverage width and 10 percent more light coverage in the rear. LED lighting packages use 45 percent less amps than standard halogen lights and have an increased life expectancy over HID lights which leads to lower costs of ownership over the life of the tractor.

NOTE: Lighting packages may vary depending on region.

Selecting a lighting mode/programmable lighting

Lighting mode selector

Lighting mode selector

Operators can quickly select a lighting mode on the steering console:

- Lights, off position

- Road lights

- Field lights

The CommandCenter™ display

The CommandCenter™ display

The CommandCenter display allows operators to customize light settings. Operators can select only the lights they need or want for a given application and store these settings. The operator-programmed configurations can then be turned on or off with the push of a button on the CommandARM™ controls.

- Programmable field lights 1

- Programmable field lights 2

- Beacon light

- Emergency flashers

NOTE: Road/loader lights are also referred to as high-mounted driving lights for use in front hitch applications that obscure the headlights. See the Attachments section.

The battery power saver feature is also standard. When the engine is off and the outside lights have been left on, this feature is designed to avoid battery run down.

After the lights have been left on for 30 minutes and the key is in the off position, the lights cycle or blink on and off five times as an alert. The lights continue to illuminate for one more minute and then automatically shut off to protect the battery.Field-installed options

Field-installed options are also available. To find this information, use the Build Your own Configurator application for US/Canada or Build & Price in John Deere Sales Centre for Australia/NZ.

Programmable exit lighting

Another feature is programmable exit lighting. Exit lighting allows the lights outside the cab to stay on for up to 300 seconds. They can be programmed in increments from 0 to 300 seconds.

Refer to the operator’s manual for complete instructions on programming field, driving, and exit lighting.

Option code Description 7201 Standard lighting 7206 Premium lighting -

Hydraulically actuated, power wet-disc brakes

The brakes are designed with large-diameter rear disc brakes and powerful activating pistons. The brakes run in oil for cooling and long life in the most demanding situations. Braking in the field during a turn can be accomplished with light pedal effort and excellent modulation of brake forces.

Hydraulically actuated, power wet-disc brakes:

- Never require adjustment

- Oil cooled for long life

- Tractors equipped with front brakes use annular pistons that automatically retract after each braking operation to reduce friction for better fuel economy

- Self-equalizing feature ensures even braking to each wheel

- Integrated backup braking capabilities built into the brake system to provide positive brake engagement should the engine or hydraulic system fail

- Brake valve is located externally of the cab to provide a quiet operating environment

An integrated park brake is included with all transmission options.

Front wet-disc brakes are included on 8R Series Tractors equipped with the 50-km/h (31-mph Independent-Link Suspension (ILS™) axle and 7R Series Tractors equipped with a 50-km/h (31-mph) Triple-Link Suspension (TLS™) Plus front axle. Front Brakes are optional equipment on the 8R 42-km/h (26-mph) ILS axle and 40-km/h (25-mph) TLS Plus front axles.

Foot brakes on tractors equipped with AutoPowr™/Infinitely Variable Transmission (IVT™) transmissions have an integrated AutoClutch™, as described in the IVT section. Similarly, foot brakes on tractors equipped with e23™ transmissions have integrated AutoClutch™, as described in the e23 section.

For towing very large loads, the 7R and 8R Series Tractors can be equipped with a complete air-brake-system or a hydraulic brake coupler, or both. The brakes supply air or oil pressure to a brake-equipped trailer or implement.

-

Gold Key Program Waterloo operations

The John Deere Waterloo Operations Gold Key Program was designed to recognize and honor those purchasing Waterloo-built tractors. The Gold Key tour provides an opportunity for a customer to follow his or her tractor as it is built on the assembly line. If a Gold Key customer is unable to visit the day the tractor is on the assembly line, the customer may elect an alternative date within 90 days to schedule a tour. This will be recognized as a Gold Key experience where the customer adopts a tractor to follow rather than watch his or her own tractor being built. After 90 days, the visit will be deemed a VIP tour and Gold Key memorabilia will not be provided.

Definition of a Gold Key tour

A Gold Key tour entails an exclusive, behind-the-scenes guided tour of the assembly production lines. The customer, or product owner, may bring up to three additional guests on the tour. Tour participants will wear Gold Key owner identification bump caps and other personal protective equipment while being escorted privately by a tour guide. Every attempt will be made to make sure the customer will see the specific tractor ordered come off the final assembly line; however, in order to satisfy delivery needs, the first priority is to keep the manufacturing lines running at full capacity.

The Gold Key visit date is based on when the customer’s tractor is expected to reach the final line. It is John Deere’s goal that a customer drives his or her tractor off the final line at the end of the tour. It is imperative to notify the John Deere dealer from whom the tractor was purchased in order to initiate a Gold Key tour. The John Deere dealer will be required to register guests on the Gold Key registration website as soon as possible if a Gold Key visit is requested. The owner will be presented with a gold key, a certificate, and other memorabilia at the conclusion of the factory visit. Breakfast and lunch will also be provided the day of the tourisit.

Process of Gold Key tour

The owner will need to notify the John Deere dealer where the Waterloo-built 6000 Series – 9000 Series Tractor was purchased. The Gold Key coordinator will be the sole contact with the dealership representative to make visit arrangements and confirmations for the visit.

Shortly after the Gold Key coordinator confirms the request, all appropriate paperwork and information will be sent to the dealer. The customer will then receive all welcome documents in the mail. The Gold Key coordinator will also make direct contact with the customer to confirm the visit.

Ahrens Farms

Ahrens Farms

Ahrens Farms of Owatonna, MN participated in the Gold Key Tour at John Deere Waterloo Works in 2015. They purchased a 9470RT Tractor.

While every attempt will be made, and the factory will do everything possible to allow a customer to see his or her tractor being built, production schedules change for many reasons. Should production change at the last minute, the owner may arrive only to find that either the tractor has been pushed back or pulled ahead and already built. While that is certainly not the intention, the possibility remains.

The factory cannot be responsible for:

-

Production delays, work ahead, or production revisions

-

Any option changes at the factory level

-

Overnight accommodations; however, assistance with information is available upon request

-

Travel costs

Gold Key Tour guidelines

- All Gold Key tours must be initiated by the selling John Deere dealer through the Gold Key profile request form.

- The Gold Key coordinator at the Waterloo Tractor Factory will be responsible for updating the customer and dealer of the tractor build status.

- Gold Key treatment will not be recognized if any of the requirements are not met prior to arrival at the factory.

- The Gold Key Program is only available within 90 days of the tractor's build date.

- Every attempt will be made to make sure the customer will see his or her tractor come off the assembly line; however, the factory has first priority for production obligations.

- Gold Key tours are limited to the customer and three other persons, no more than four people total (excluding dealer).

- All guests attending Gold Key tours must be 13 years of age or older. Any teenage children must be accompanied and under constant supervision of a parent and/or guardian.

- No personal cameras or video cameras are allowed on the production floor during the tour. A camera from John Deere will be given to Gold Key guests for the duration of the tour.

- Tour participants must abide by all factory tour safety rules and regulations.

- Gold Key tours will be restricted if maximum tour capacity has been reached due to previously scheduled tours or special events.

-

-

Premium CommandView™ III cab with suspension offers unsurpassed amenities

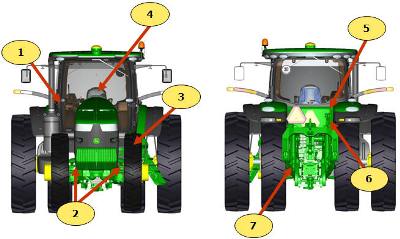

CommandView III cab

CommandView III cab

The Premium CommandView III cab offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality.

Features:- ComfortCommand™ seat with air suspension and lumbar support, swivel, fore-aft and lateral attenuation, backrest angle adjustment, adjustable left-hand armrest, and 40-degree right-hand seat swivel

- Four-corner cab suspension

- Behind-the-seat storage and left-hand storage compartment

- Folding instructional seat

- Beverage holders sized to accommodate various containers

- Interior left-hand dome light

- Tilt/telescoping steering wheel with position memory

- Adjustable right-hand CommandARM™ armrest controls with integrated CommandCenter™ display

- Monitor mounts on right-hand front post and rear cab post

- Digital cornerpost display with:

- Fuel level gauge, including low fuel warning

- Temperature gauge

- Diesel exhaust fluid (DEF) gauge, including low DEF warning

- Engine rpm

- Transmission commanded gear or speed

- Vehicle system functions, such as iTEC™ system, that are operating

- Swing-out rear window that opens 30 degrees

- Front, rear, and right-hand windshield wiper and washer

- Two-speed and intermittent front and rear wiper

- Front, rear, and right-hand side sunshades

- Right and left outside wide-angle mirrors (electrically adjustable and heated)

- Inside-mounted rearview mirror

- Roof-mounted license plate bracket with light

- Window break

- Pin for tow point

- Passive noise reduction system

- Laminated glass

- Service ADVISOR™ data port

- Power strip with convenience plug adapter

- Two 12-V convenience outlets (cigarette lighter style)

- One 12-V 3-pin outlet with adapter (provides switched and unswitched power)

- One International Organization for Standardization (ISO) 9-pin connector

- Standard radio package, including AM/FM stereo and weatherband with remote controls, auxiliary input jack, four speakers, and an external antenna

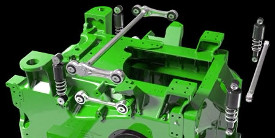

Four-corner cab suspension

8RT Series Tractors feature the Premium CommandView III cab with cab suspension in base. Producers will enjoy all the features they have come to expect in the Premium CommandView III cab plus the addition of improved ride quality in the field and on the road with the cab suspension. The cab suspension, combined with the proven AirCushion™ suspension system, will give John Deere operators the most comfortable operating experience available in a two-track tractor.

Four-corner cab suspension system

Four-corner cab suspension system

Cab suspension components

Cab suspension components

Cab suspension components

Cab suspension components

Cab suspension components

Cab suspension components

Steering system

Steering sensitivity adjustment screen

Steering sensitivity adjustment screen

Steering pump and loop override circuit

Steering pump and loop override circuit

Steering circuit change and steering sensitivity adjustment

8RT Series Tractors include an improved steering pump, changes to the loop-override circuit, and in-cab steering sensitivity adjustment.

The improved steering pump and changes to the loop-override circuit increase steering response and steering authority on 8RT Series Tractors. Operators will notice this change when working in heavy draft, soft field conditions, and obstacle avoidance. The steering pump and loop-override circuit give the 8RT the ability to turn under load like no other two-track tractor in the industry.

8RT steering sensitivity adjusted in the 4600 CommandCenter Display

This feature allows operators to fine tune the steering system based on the application or environment.

Steering sensitivity adjustment does not only help when steering the tractor manually. Operators using guidance systems will also experience improved response with the ability to input tractor tread settings in the 4600 CommandCenter Display. From there, the tractor will control the steering pump to ensure steering is consistent no matter which tread setting the operator is utilizing.

Pull-down front, rear, and right-hand sunshade

Pull-down sunshades

Pull-down sunshades

These variable-length sunshades provide excellent adjustability to keep direct sun off of the operator. Perforations in sunshade material provide visibility through the sunshade as well. The sunshades are also recessed into the headliner for storage when not in use.

Right- and left-outside mirrors, electrically adjustable

Right-hand mirror shown on 8RT Series Tractor

Right-hand mirror shown on 8RT Series Tractor

Right and left outside wide-angle mirrors are electrically adjustable with simple in-cab adjustments to view variable-width implements, wagons, or carts. The in-cab controls are located directly above the radio.

Leather comfort option

The leather seat option is available on 8RT Series Tractors. The kit includes leather operator seat, leather instructional seat, leather-wrapped steering wheel, rear window decal, and carpet floormat.

NOTE: The leather comfort package is not available with Scraper Special Tractors.

Leather seats

Leather seats

Leather-wrapped steering wheel

Leather-wrapped steering wheel

Rear window decal

Rear window decal

Seat swivel

Seat swivel

Seat swivel

The design of the CommandARM controls allows for up to 40 degrees of right-hand seat swivel.

Transmission controls

John Deere 8RT Series Tractors equipped with the e23 transmission with Efficiency Manager feature or AutoPowr™ IVT transmission feature either a left-hand or right-hand reverser.

The transmission control lever is placed on the CommandARM control’s left side closest to the operator for convenient setting and adjustment.

Left-hand IVT and PowerShift™ transmission reverser

Left-hand IVT and PowerShift™ transmission reverser

Right-hand IVT and PowerShift transmission reverser

Right-hand IVT and PowerShift transmission reverser

Throttle

The throttle design incorporates buttons which control FieldCruise speed, foot pedal mode (if equipped), and transmission eco settings.

ComfortCommand seat

ComfortCommand seat

ComfortCommand seat

The ComfortCommand seat with air suspension improves ride quality and helps to reduce operator fatigue. The ComfortCommand seat with air suspension is offered with cab suspension. The ActiveSeat™ is available on fixed cab tractors.

Features include:- Armrests, lumbar support, and backrest angle are easily adjusted to match operator preference

- Shock absorbers dampen the motion effect of the tractor for an improved ride

- Seat height adjustments are conveniently located on the left armrest

- Fore-aft adjustment is easy to reach located on the left front of the seat

- Swivel adjustment, located on the front of the seat, allows the seat to be swiveled 40 degrees to the right or eight degrees to the left of the center position

- Operator presence switch warns if the operator is out of the seat while operating key functions

- Seat belt retractor

- Centered cab seat, providing excellent over-shoulder visibility

- Adjustable shock absorber permitting ride adjustment from soft to firm to match the operator's desired comfort level

- Removable cushions for easy cleaning

CommandARM

CommandARM controls

CommandARM controls

John Deere 8RT Series Tractors feature the CommandARM with integrated Generation 4 CommandCenter display. The control layout of the CommandARM utilizes a clean and efficient design which groups controls by function and builds upon John Deere’s history of intuitive and ergonomic control placement and operation. The CommandARM control’s design allows for a 40 degree right seat swivel and adjustable positioning matching the operator’s preference.

Controls located on the CommandARM include:

- Engine throttle

- FieldCruise™ system

- Minimum engine speed – e23™ transmission with Efficiency Manager™ feature, Infinitely Variable Transmission (IVT™)

- Eco mode

- Foot pedal lock (if equipped)

- Transmission control

- Hitch/selective control valve (SCV) controls

- Rotary encoder hitch control

- Power take-off (PTO) controls

- iTEC sequence switches

- AutoTrac™ assisted steering system resume switch (if equipped)

- Joystick (if equipped)

- Radio

- Beacon light on/off

- Hazard lights on/off

- Field lights 1/2

- Heating, ventilation, air conditioning (HVAC) system

Hydraulic and hitch controls

Hydraulic and hitch controls utilize fingertip paddle pots for raise/lower and extend/retract functions. An optional crossgate joystick replaces fingertip paddle pots for control of SCVs and allows for programmable hydraulic functionality according to operator preference. Rear hitch position can also be controlled with the encoder wheel located on the right side of the CommandARM. The encoder wheel allows for finite positioning of the rear 3-point hitch.

Three buttons near the encoder are for hitch set, lock, and return to height. Adjustment for the 3-point hitch is done via the CommandCenter display.

Fingertip paddle pots

Fingertip paddle pots

Encoder wheel

Encoder wheel

Optional crossgate joystick

Optional crossgate joystick

Throttle

Throttle

Foot throttle

Foot throttle

Tractor function controls

Located just to the right of the throttle is the AutoTrac activation button and four sequence controls for iTEC functions.

AutoTrac resume and iTEC strip

AutoTrac resume and iTEC strip

Controls for radio, lights, rotary beacon (if equipped), hazard flashers, and HVAC system are located to the center-right on the CommandARM, along with PTO for both front (if equipped) and rear.

Radio, HVAC, hazard flashers, and PTO controls

Radio, HVAC, hazard flashers, and PTO controls

CommandCenter display

Generation 4 CommandCenter display

Generation 4 CommandCenter display

The Generation 4 CommandCenter displays feature fast adjustment of tractor functions and controls and are integrated into the CommandARM to create a seamless control center. The 4600 CommandCenter features a 26.4-cm (10.4-in.) touchscreen display and is standard equipment on 8RT models.

The following functions can be adjusted using the CommandCenter display:

- Hydraulic settings

- Hitch settings

- Transmission settings

- FieldCruise

- iTEC programming functions

- Radio

- Lights

-

Front power take-off (PTO) options for increased versatility

Front PTO

Front PTO

For increased versatility, two 1000-rpm front PTO options are available from the factory for 7R and 8R Series Tractors equipped with the John Deere front hitch.

- Type 2, 1000-rpm (counterclockwise as seen from front), 35-mm (1 3/8-in.), 21-spline front PTO

- Type 3, 1000-rpm (counterclockwise as seen from front), 45-mm (1 ¾-in.) 20-spline front PTO (available through Parts only)

Front PTO features include:

- The ability to be incorporated with iTEC™ sequences

- Three choices of engagement modulation: auto, low, and high

- Integrated controls

- Cornerpost display indicators

- Bolt-on shaft makes it easy to change shafts if necessary.

- Remote PTO engagement

7R specific features:

- 130 kW (175 hp)

- Integrated with all transmissions

- PTO disconnect for efficiency

- Requires Triple-Link Suspension (TLS™) front axle

8R specific features:

- 112 kW (150 hp)

- Integrated with the infinitely variable transmission (IVT™)

- Requires Independent-Link Suspension (ILS™) with front brakes

Intelligent Power Management (IPM)IPM is compatible with 7R and 8R Series Tractors equipped with a front PTO option. The front PTO, rear PTO, or transport speeds can activate IPM on 7R Tractors. However, on 8R Tractors, IPM is only activated by the rear PTO or by transport speeds. For example:

- A front snow blower will not benefit from IPM on an 8R since the front PTO alone will not activate IPM.

- A triple-mounted mower-conditioner will benefit from IPM as high power levels are transmitted via the rear PTO. The front mower-conditioner will have 112 kW (150 hp) available to it on an 8R, which is adequate to operate these mowers in most crop conditions.

- See Intelligent Power Management for more information.

PTO disconnect on 7 Family Tractors

Disconnecting the PTO drive to the PTO box when not in use increases tractor efficiency by reducing:

- Power requirements, which saves nearly 70 percent of power required to run the PTO disengaged

- Wear on components of the PTO box; components are not moving when the PTO is disconnected

Refer to the Operator’s Manual for instructions on how to disconnect the PTO when not in operation.

Front PTO operation

Remote control at front of tractor

Remote control at front of tractor

Front PTO engagement is actuated through an engagement switch similar to the rear PTO located on the CommandARM™ controls.

- PTO clutch is electronically activated with automatic torque modulation.

- PTO modulation is selectable through the CommandCenter™ display.

- To activate the PTO remotely, select the remote PTO enable button in Generation 4 CommandCenter display, push down and forward on the front PTO switch in the cab and use the remote control at the front of the tractor.

NOTE: For the 8R Series, if the tractor is equipped with a front PTO, additional IPM power will transfer through the front PTO. However, IPM activation is only sensed through the rear PTO. Adequate load must be sensed on the rear PTO in order for IPM to activate.

-

ActiveCommand steering (ACS™) provides a robust and full-encompassing steering system

ACS overview

8R in transport

8R in transport

With ACS, John Deere has designed one of the most robust and full-encompassing steering system in the industry. Whether in the field or on the road, ACS reduces steering effort, which can result in reduced operator fatigue and can improve operator comfort.

There are four key features of the ACS system:

Dynamic road wheel offset:

- A gyroscope senses tractor yaw and can automatically make small steering adjustments to provide unprecedented line-holding abilities. Drive down a bumpy road and experience how ACS makes it easier to keep the tractor straight, even over rough terrain. ACS delivers the ultimate in comfort.

- ACS works to prevent over-steering when a sudden obstacle causes the operator to make a quick steering reaction.

Variable ratio steering:

- Approximately 3.5 turns lock-to-lock at in-field speeds for quick headland turns.

- Approximately 5 turns lock-to-lock at transport speeds.

Elimination of steering slop and hand wheel drift:

- Steering wheel drift and slop are eliminated with the ACS electronic control system.

Variable effort steering:

- Steering wheel resistance automatically changes with ground speed to deliver light steering effort at slower speeds for less effort during headland turns, and higher steering wheel torque at transport speeds for better comfort.

A fail operational system

The ACS system is fail operational, which means steering is still functional in the event of any single-point failure. John Deere has gone to great lengths to help ensure the operator has the ability to steer the tractor if something goes wrong in the steering system.

For example, if the primary controller fails, a second controller takes over. If power from the alternator fails, the battery resumes control. If the engine quits running and is unable to supply hydraulic oil to the system, an electric-driven backup pump is used to supply the oil. There is a backup for ACS components. ACS components

ACS components

The ACS system consists of several key components:

- Gyroscope: this is used to measure the yaw rate (turn rate) of the tractor during transport speeds.

- Road-wheel angle sensors: these sensors simply measure the steer angle of the tractor.

- Power supply module: this module distributes the power of the battery and alternator throughout the ACS system.

- Hand-wheel angle sensors and tactile feedback unit: this includes the steering wheel position sensors and a brake which can increase or decrease resistance dependent on speed. Lighter feedback is desired during normal field use, and slightly heavier feedback is desired during transport and while the tractor is cornering at high speeds.

- Controllers: two controllers are located in the back of the tractor and are the brains of the system.

- Control valves: also known as steering valves, control valves are used to steer the tractor.

- Electric-drive backup pump: this pump supplies oil to the steering system, brakes, and park (for towing) brake if there is no longer a sufficient oil supply to the steering and brakes.

Value of ACS

- Improves line holding when driving at transport speeds

- Fewer turns lock-to-lock: 3.5 turns lock-to-lock in the field for quicker headland turns and 5 turns lock-to-lock at transport speeds

- Eliminates hand wheel backlash and drift

- Reduces steering effort results in reduced operator fatigue

- Smaller hand-wheel diameter for improved operator comfort and visibility

- Maintains operator feel and touch-points of traditional steering column system

- Fully integrates with AutoTrac™ guidance assisted steering stems

- Compatible with suspended and non-suspended front axles

- Compatible with wide and narrow section width tires

-

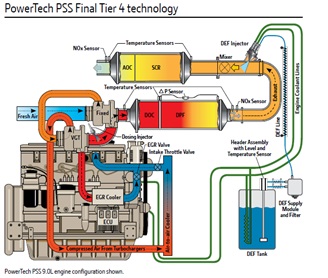

Cooled exhaust gas recirculation (EGR)

PowerTech™ PSX 9.0-L engine

PowerTech™ PSX 9.0-L engine

How exhaust gas recirculation (EGR) works

EGR reduces the high temperatures where nitrogen oxide (NOx) compounds are formed in the engine cylinders by replacing excess oxygen with a prescribed amount of cooled exhaust gas.

Exhaust gases contain more carbon dioxide than oxygen. The EGR valve in conjunction with the venturi and engine control unit (ECU) allows a controlled amount of exhaust gas to enter the intake manifold to mix with the incoming fresh air. Replacing excess oxygen with cooled exhaust gas leads to lower combustion temperatures, creating less NOx. In addition, EGR allows for advanced timing, leading to optimal performance of the engine, maximizing fuel economy.

The following diagrams illustrate how air flows through the engine.

For added performance and efficiency, the engine passes the exhaust gases through an EGR cooler before it enters the engine. PSS engine diagram

PSS engine diagram

Flow of exhaust during engine operation

Exhaust airflow enters into the EGR cooler from the exhaust manifold near the turbocharger.

Based on engine load, air temperatures, and rpm, the engine control unit (ECU) opens or closes the EGR valve, allowing a measured percentage of exhaust gas to enter the intake manifold.

The gases mix with the rest of the incoming air from the turbocharger and aftercooler before entering the cylinders. -

Take advantage of the Generation 4 CommandCenter™ display, designed for efficiency

The Generation 4 CommandCenter was designed to provide a consistent user experience by providing full-screen viewing of more run page modules, shortcut keys, and precision agriculture capabilities.

Expect easier set-up, along with increased operator confidence, thanks to a simple, customizable interface. The improved design of the Generation 4 CommandCenter also aids in an optimal operating experience and maximizes uptime.

In order to increase your efficiency, take advantage of the following features offered by the Generation 4 CommandCenter:Layout manager

Layout manager selection page

Layout manager selection page

Layout manager module build

Layout manager module build

- Easily create page views that meet your needs and that are also equipped with default run pages.

- Users and access allow the owner or manager to lock out certain functions to prevent operators from accessing or changing settings with a defined four-digit code.

- Gather on-screen help by selecting the help icon on the shortcut bar on the bottom of every page.

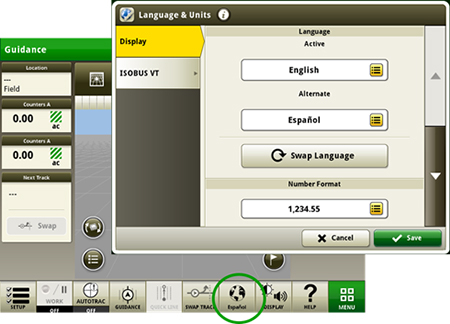

Language and units

Switch between active and alternate language on the display

Switch between active and alternate language on the display

Easily switch between languages with the option to set the active and alternate language. Configure the shortcut bar to include the language toggle allows different individuals to easily switch the display between languages.

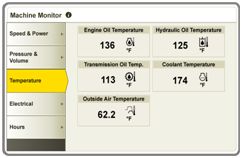

Machine monitor

Machine monitor page

Machine monitor page

- The Machine Monitor application provides you instantaneous readings about the status or condition of your machine.

- This application shows parameters such as engine speed, coolant temperature, and ground speed.

Work monitor

Work monitor page

Work monitor page

- The Work Monitor application displays performance information about the task being performed by the machine.

- You are shown averages, totals, and productivity of the machine, such as area worked, average working speed, and fuel usage.

- Work setup places the settings needed to properly setup features such as AutoTrac, Documentation, and Section Control in a single location. Settings include:

- Client, farm, and field

- Crop type

- Machine and implement dimensions

- Variety/hybrid and planting/seeding rates

- Variable rate prescriptions

- Product and application rates

- Application rates through the implement screens

Video looping supported with Gen 4 4600 CommandCenter Display and 4640 Universal Display

- This feature enables users to scan or loop through all of the available video feeds for a specified duration. The default scan time is set to 7 seconds per image. The scan time is customizable per image allowing for consistent visibility to all video feeds.

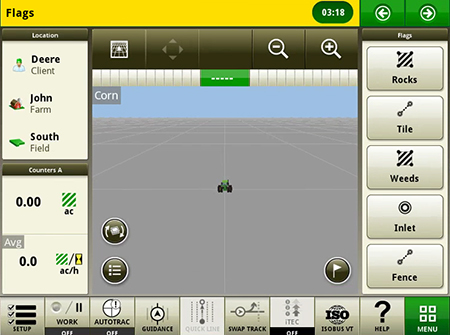

Flags

Create flags to mark items in the field

Create flags to mark items in the field

- Mark areas in the field that need special attention such as rocks, tile lines, or weed pressure.

- Flags previously recorded on the Gen 4 or GreenStar™ 3 2630 Display can be transferred between monitors.

- Flags previously recorded on the Gen 4 or GreenStar™ 3 2630 Display can be transferred between monitors.

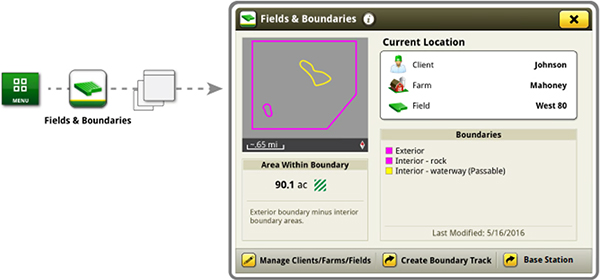

Automatic base station switching

Setup base stations in Fields and Boundaries applications

Setup base stations in Fields and Boundaries applications

- Customers using John Deere RTK Radio 450 or 900 can link a base station to a desired client,/ farm,/ or field. This allows automatic switching to the associated base station when changing fields. The ability to import base station assignments into Operations Center and send back to machines will be available at a later date.

Dual-display mode

Dual display

Dual display

- Generation 4 CommandCenter may be configured to run with the following John Deere displays connected at the cornerpost of a John Deere tractor:

- GreenStar 2 1800 Display

- GreenStar 2 2600 Display

- GreenStar 3 2630 Display

- 4640 Universal Display

- 4240 Universal Display

NOTE: Vehicle applications will always be located on the Gen 4 CommandCenter.

Video capability

- Machines equipped with a 4200 CommandCenter are equipped with one video input, and the 4600 CommandCenter has four video inputs.

- You have the ability to set a variety of triggers. With each trigger, the image will then appear on the display.

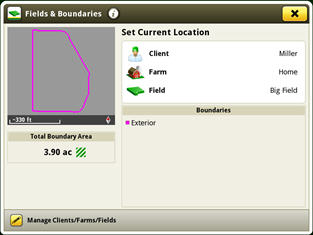

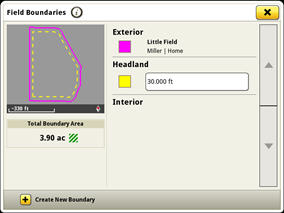

Field boundaries

Boundary creation from coverage

Boundary creation from coverage

Headland creation

Headland creation

- Manually drive field boundaries with the Generation 4 CommandCenter or import existing boundary information from the GreenStar 3 2630 Display or John Deere Operations Center. Gen 4 documentation data can be used to create boundaries from coverage within the John Deere Operations Center.

- Easily create page views that meet your needs and that are also equipped with default run pages.

Capacities

| Crankcase oil volume | 25 L 6.8 U.S. gal. |

| Transmission-hydraulic system | 180 L 47.5 U.S. gal. |

| Fuel tank | 750 L 200 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 25.3 L 6.7 U.S. gal. |

| Cooling system | 32.6 L 8.6 U.S. gal. |

Drawbar

| Drawbar category | Standard: Category 4 Optional: Category 4 with heavy duty support |

| Maximum vertical load | Standard: 2,245 kg 4,950 lb Optional: 4,990 kg (11,000 lb) (dependent on drawbar position) |

Electrical system

| Alternator size | Standard: 200 amp |

| Total cold cranking amps | 1,850 CCA |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| Battery options | 12 V |

| Type of bulb in headlight (Halogen, Zenon, LED) |

Engine performance

| Power boost | 10 percent |

| Engine peak torque | At 1600 rpm: 1,615 Nm 1,191 lb-ft |

| PTO torque rise | 40 percent |

| Rated power | 97/68EC: 254 kW 345 hp |

| Rated PTO power (hp SAE) | 208 kW 280 hp |

Engine specifications

| Rated speed | 2,100 rpm |

| Emission level | Final Tier 4 |

| Description | John Deere PowerTech™ PSS 9.0 L (B20 diesel compatible) |

| After treatment type | DOC/DPF/SCR |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with 4 valves-in-head |

| Displacement | 9 L 549 cu in. |

| Aspiration | Dual series turbocharger with fixed geometry first stage, variable geometry second stage; air-to-air aftercooling and cooled exhaust gas recirculation |

| Engine family | JJDXL09.0308 |

Hydraulic system

| Available flow at a single rear SCV | 0.5 in. couplers: 132 L/min 35 gpm 0.75 in. couplers: 159 L/min 42 gpm |

| Pump rated output | Standard: 85-cc pump: 227.1 L/min 60 gpm |

| SCV control | Electronic |

| Number of rear selective control valves (SCVs) | Standard: 0.5 in. ISO couplers: 4 Optional: 0.5 in. ISO Couplers: 5 and 6 available 0.75 in. ISO coupler: 1 |

| Type | Closed-center, pressure/flow compensated |

Key Specs

| Transmission type | Standard: John Deere AutoPowr™ IVT™ 40K, 0.050-42 km/h 26 mph Optional: e23 Powershit with Efficiency Manager™ 40K, 40 km/h |

| Base machine weight | 15,365 kg 33,871 lb |

| Engine displacement | 9 L 549 cu in. |

| Engine description | John Deere PowerTech™ PSS 9.0 L (B20 diesel compatible) |

| Hydraulic pump rated output | Standard: 85-cc pump: 227.1 L/min 60 gpm |

| Rated engine power | 97/68EC: 254 kW 345 hp |

| Rear hitch category (SAE designation) | Standard: Category 4N/3: 6,803 kg (15,000 lb) at 610 mm behind hitchpoint Optional: Category 4N/3: 9,072 kg (20,000 lb) at 610 mm behind hitchpoint |

| Rated PTO power (hp SAE) | 208 kW 280 hp |

Miscellaneous

| Country of manufacture | USA |

Operator station

| Display | Standard: 4100 Generation 4 CommandCenter™ with 7 in. display Optional: 4600 Generation 4 CommandCenter™ with 10 in. display |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna |

| Inner cab volume | 3.597 m3 127 cu ft |

| Seat | Standard: ComfortCommand™ Optional: ActiveSeat™ |

| Rollover protective structure, OOS | |

| Cab glass area | 6.52 m2 70.18 sq ft |

| Instructional seat | Standard |

Precision AG

| Guidance | AutoTrac Ready |

| Remote diagnostics | Available with activated JDLink™ hardware and activations |

| Telematic | Available with JDLink™ hardware, activations, and Ethernet Harnesses (availability dependent upon destination) |

Rear axle

| Final drive type | Inboard planetary |

Rear hitch

| Maximum lift capacity behind lift points | Category 4 4N/3: 9,072 kg (20,000 lb) at 610 mm behind hitchpoint |

| Hitch category (SAE designation) | Standard: Category 4N/3: 6,803 kg (15,000 lb) at 610 mm behind hitchpoint Optional: Category 4N/3: 9,072 kg (20,000 lb) at 610 mm behind hitchpoint |

| Sensing type | Electrohydraulic |

Rear power take-off (PTO)

| Type | Independent Standard: 44.45 mm (1.75 in.) 20-spline, 1,000 rpm |

| Engine rpm (at rated PTO speeds) | 1,000 PTO rpm @ 2,000 engine rpm |

Serviceability

| Interval for engine coolant change | 6,000 hours |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

Steering

| Type | Standard: Speed-sensitive, hydrostatic, differential: 406 mm diameter steering wheel - 1.8 turns lock-to-lock |

Tires

| Wheel tread range | 1,828.8 to 3,048 mm 72 - 120 in. 2,844.8 to 4,064 mm 112 - 160 in. |

Transmission

| Type | Standard: John Deere AutoPowr™ IVT™ 40K, 0.050-42 km/h 26 mph Optional: e23 Powershit with Efficiency Manager™ 40K, 40 km/h |

Weight

| Base machine weight | 15,365 kg 33,871 lb |

| Maximum permissible weight | 19,958 kg 44,000 lb |

| Maximum ballast level | 17,690 kg 39,000 lb |