Impeller conditioner

Impeller conditioner

Impeller conditioner

Exclusive impeller conditioner is available for the 994 Rotary Platform. Proper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted.

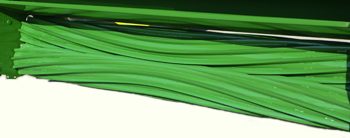

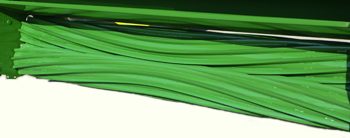

How an impeller conditioner works:

1. As hay is cut by rotating knives, 72 V-shaped tines pick up plants and carry them through the machine. The free-swinging design reduces damage to the conditioner if rocks or other solid objects are struck.

- Tines are evenly spaced along the full width of the rotor

Conditioning hood

Conditioning hood

2. As the plant passes through, it rubs against the conditioning hood (A) and other plants. A rubbing action removes the waxy surface from the stem of the plant to allow faster evaporation of moisture.

3. The conditioner hood is adjustable to control the conditioning intensity. The wider the opening, the less aggressive the conditioning; this is used in legume-type crops. The smaller the opening, the more aggressive the conditioning; this is used more in grass hay.

4. The impeller has two speeds to match crop conditioning requirements:

- Simply interchange the drive sheaves

- High speed of 865 rpm for grass hay

- Low speed of 624 rpm for legumes

The impeller conditioner works well in legumes, especially alfalfa and most all-grass crops. Impeller conditioners are not recommended for thick-stemmed or cane-type crops over 1.5-m (5-ft) tall.

Urethane conditioning rolls

Urethane conditioning rolls

Urethane conditioning rolls

The urethane roll conditioner works well in legumes, especially alfalfa and most all-grass crops. In general, roll conditioners are better suited for thick-stemmed, cane-type, and taller grasses over 1.5-m (5-ft) tall.

Molded urethane rolls are formed by a cool molding process that does not distort or warp the steel core of the roll and ensures the rolls are arrow straight and cylindrical, so they can be accurately spaced close together for uniform conditioning along the length of the roll.

The intermittent recessed cleat design gives more crimping edges for greater pressure per square inch, which results in superior conditioning and faster crop drying.

V-10 steel conditioning rolls

Close-up of V-10 steel conditioning rolls

Close-up of V-10 steel conditioning rolls

The V-10 steel conditioner rolls feature 10 angled flutes arranged in a chevron, or V, pattern along the length of the steel core.

The steel rolls offer improved wear life over urethane rolls, particularly in adverse crop conditions.

Advantages of the V-10 conditioner roll over the previous straight flute design include the following:

- Deep intermeshing angles for positive feeding and uniform conditioning throughout the entire length of the rolls

- More crimping edges for improved conditioning

- Improved feeding

- Improved windrow formation

Tri-Lobe™ steel conditioning rolls

Tri-Lobe steel conditioning rolls

Tri-Lobe steel conditioning rolls

Close-up of Tri-Lobe steel conditioning rolls

Close-up of Tri-Lobe steel conditioning rolls

Tri-lobe steel conditioning rolls have three intermeshing chevron lobes to crush the length of the stem for improved conditioning and faster drydown. The rolls are manufactured using a patented process.

The steel material increases wear life, especially in abrasive crops or soil conditions. Durability is a distinct advantage compared to other crusher-style rolls made of rubber or urethane. The chevron design of the rolls gives positive feeding and improved crop flow.

These rolls are well suited for use in alfalfa, where a reduced curing time results in less bleaching of the crop. In heavy, thick-stemmed crops, such as sudan or sudex, the steel construction of the rolls does a very good job of breaking up the nodes on the stems to improve drydown.

Replaceable end shafts

Replaceable end shafts

The shafts on the Tri-Lobe rolls are steel forgings that are then machined. These precision parts have minimal run-out, which means the rolls themselves rotate precisely around their axis.

This precision enables the rolls to be adjusted to a minimum clearance for consistent conditioning along the length of the rolls.

The machined, forged roll ends are bolted into the core of the Tri-Lobe steel roll. In the event a roll end were to be damaged, the entire roll does not need to be replaced. Each shaft can be replaced individually, resulting in lower repair costs.

For serviceability, each roll end has two threaded holes so bolts can be used to pull the shafts from the steel core of the roll.