C500 Mower-Conditioner

- John Deere

- Mower-Conditioners

Find Your Nearest Location

Key Features & Specs

- 16 ft 4 in. (5 m) cutting width

- Reduce service time with Quick Change Knives

- Easier serviceability with modular-design cutterbar

- Improve windrow formation and reduce ash content with overshot cross auger

- Urethane, V-10 conditioners or Tri-Lobe conditioners

- Cutting Height 0.63 to 6.7 in. (1.6 to 1.7 cm)

- Cutting Width 16 ft. (4.9 m)

- Discs 10

- PTO Speed 1,000 rpm

- 540-rpm PTO, 1 3/8" shaft N/A

- 1,000-rpm PTO, 1 3/8" shaft 120-210 hp (89-157 kW)

- + Expand All

- - Close All

-

Protect your crop with conditioner options to fit your needs

C400 Mower-Conditioner

C400 Mower-Conditioner

Achieving the right conditioning action can significantly reduce dry down time. That means less time needed to cure, maintaining optimum feed values, and preventing leaf loss in legumes. Hay and forage producers have a wide variety of crops and conditions. That’s why John Deere mower-conditioners offer four different conditioners.

- Conditioning reduces the time required for dry down

- Multiple conditioner options match a wide variety of crop types

- Faster dry down can increase nutrients retained in harvested crops

- Suitable for traditional dry hay or haylage operations

Conditioner types include:

- Impeller – ideal for light-stemmed grasses and alfalfa that respond well to scuffing of the stems

- Urethane – a soft roll that provides excellent performance in legumes and grasses

- V10 steel – increased crimping for faster dry down and improved wear life

- Tri-Lobe™ conditioner – a premium, patented roll system that uses a chevron design to crimp and crush

-

Save time with quick-change knives

Quick-change knives

Quick-change knives

Having sharp knives on your machine is critical to harvesting all your crop and leaving a clean-cut field. Changing dull or bent knives is no longer a time-consuming job with the John Deere quick-change knife (QCK) system. There are no worries about having an impact or air compressor to change out the bolts. Simply insert the QCK tool into the disk and press down. The knives can be swapped out in seconds.

- Reduce time to change knives by more than 50 percent over the bolted system

- Base equipment for every John Deere mower conditioner

- Kits are available to retrofit most 600, 800, and 900 Series Mower-Conditioners

-

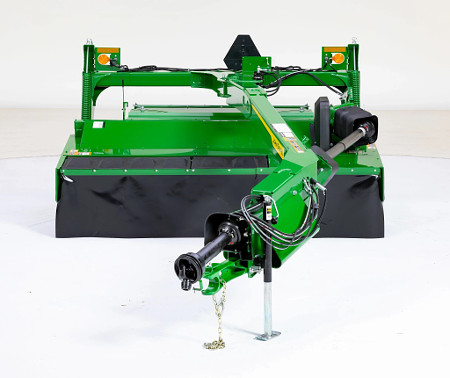

Maximize productivity with the C500 Center-Pivot Mower-Conditioner

C500 Center-Pivot Mower-Conditioner

C500 Center-Pivot Mower-Conditioner

The C500 Center-Pivot Mower-Conditioner from John Deere offers you the widest cut in the lineup. The 5-m (16.4-ft) wide platform is the center-pivot equivalent of the commercial-grade 500R Windrower Platform. The C500 is built to withstand the needs of custom operators and producers covering high acres in a season.

- The C500 allows you to cut 10 percent more acres per day versus the C450

- Four conditioner options – Impeller, V10 steel roll, urethane roll, or Tri-Lobe™ steel roll

- Replace knives in a fraction of the time with quick-change knives

- The C500 has an overshot cross auger that improves crop flow, providing optimal windrow formation:

- Lifts blown down crop for a clean cut

- Converges the crop and keeps it from stalling on the cutterbar to minimize recut

- Converges the crop mat into the conditioning rolls for more consistent crimping

- Large forming shields to customize windrow width

Cut more acres per season or cut the same acres in less time. The C500 improves productivity, helping you harvest more crop while the conditions are right.

-

Quickly prepare the mower-conditioner for transport

Overview

C400 in transport

C400 in transport

An advantage John Deere has over most competitors is that the mower-conditioners transport directly behind the tractor at nearly the same width as its cut. Operators can transition from road to field configuration and back again quickly and easily.

- Quickly move between fields when road transport is required

- Minimize transport dimensions for improved narrow road transport

Side-pull model in transport position

Side-pull model in transport position

Side-pull models (S250, S300, and S350) have the tongue positioned in the center of the frame and drivelines that enter from the top to improve transport width.

The C450 also has provisions to allow end-wise transport if you already have a dedicated transport cart. After backing the machine onto the cart and securing it, the tongue can be positioned parallel with the cutting head, allowing it to be towed by the tractor at under 2.8 m (9.2 ft).

-

Minimize dry down time with proper windrow formation

C400 windrow formation

C400 windrow formation

Windrow formation is the final step of mower-conditioner functionality. Proper windrow formation is critical to reducing dry down times for dry hay and haylage or providing consistent chopping speeds and cut lengths for forage harvesting applications.

Characteristics of a quality windrow include:

- Consistent volume of crop throughout the windrow

- No clumping of material that can lead to inconsistent dry down

- Square shoulder and even edges

Sized to the width of the harvesting equipment or spread wide to allow for maximum exposure

John Deere mower-conditioners allow you to customize windrows to match your needs.

- Crop quality is maintained for higher feed value.

- Windrow width can be matched to harvesting equipment.

- Spread crop wide to maximize exposure (up to 337.8 cm [133 in.] with a properly equipped C400), further reducing dry down times.

S models - swath board adjustment

S models - swath board adjustment

C models - swath board adjustment

C models - swath board adjustment

Adjustable swath boards help direct crop coming through the conditioner assembly, providing a quick adjustment to windrow width.

- No tools required for easy in-field adjustments

- Used to make large adjustments to windrow width

Forming vanes mounted to swath board

Forming vanes mounted to swath board

0 Series Mower-Conditioners come standard with forming vanes on the swath board when available. Previously referred to as a wide swath kit, the forming vanes allow the mower-conditioner to increase windrow widths up to 25 percent and can be used to further customize windrow formation to match crop conditions.

- Install all vanes directing crop flow outward to provide the widest windrow and fastest curing

- Use vanes to direct heavy crop flow for more even distribution and consistent drying

- When not in use, forming vanes can be stored on the machine for easy access

C400 wide windrow

C400 wide windrow

The C400 produced the widest windrow when tested against a competitive machine, providing a windrow of conditioned alfalfa that was over 337.8 cm (133 in.). This was over 84 percent of the cut width for the C400 compared to 72 percent for the competition.

C500 narrow forming shield position

C500 narrow forming shield position

C500 wide forming shield position

C500 wide forming shield position

Forming shields allow fine-tuning of the windrow width. This can allow you to easily match the windrow to your tractor’s tire spacing and prevent driving on cut and conditioned crop.

- No tools required for easy in-field adjustments

- Allow the operator to fine-tune the windrow width to match equipment and dry-down needs

- Operator can easily set windrow width as required because of changes in crop type, conditions, and operating speed

-

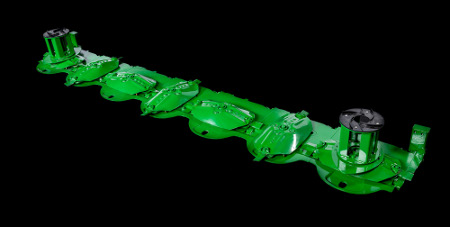

Reduced maintenance and proven cutterbar reliability with 5-year coverage

John Deere cutterbar with individual modules

John Deere cutterbar with individual modules

John Deere's patented design cutterbar is made from individual, diagonal-cut modules, making serviceability easy. Each module can be removed for service individually, leaving the remaining cutterbar modules attached to the frame.

- Nodular iron modules are highly resistant to impact damage

- Large, heavy-duty idler gears reduce driveline speed and wear

- Shear hub protection minimizes cost and decreases repair time in the field

- Gauge shoes provide accurate control of cut height and protect cutterbar

- Low-profile cutterbar allows the operator to cut at a flatter angle for improved cut quality and reduced wear on components

- Common oil bath keeps internal components lubricated and reduce oil-level checkpoints

Because John Deere is confident in the reliability, every mower conditioner includes a 5-year warranty on cutterbar components. This gives you peace of mind knowing that if you do experience a warrantable failure, your machine is backed through your experienced, local John Deere dealer.

Shear hub

Shear hub

Each cutting disk is attached to a shearhub (driver) on the splined pinion gear. Power to the disk is interrupted when the driver shears to protect the internal components of the cutterbar. Damage is limited to exposed components and does not require disassembly of the cutting modules.

- Reduces damage to the cutterbar and driveline components

- Improved uptime with limited disassembly required

Gauge shoe

Gauge shoe

The gauge shoe setting determines the height of the crop stubble, but also prevents the majority of the cutterbar from being in constant contact with abrasive soils and rocks. The S250, S300, S350, C300, C350, and C400 have three height adjustments on the gauge shoe. The C450 and C500 come from the factory with six adjustments. Through service attachments, gauge shoe extensions are available to increase the number of adjustments if there is a need for higher stubble height.

Cutterbar

| Cutterbar protection | ShearHub |

| Lubrication | Hy-Gard oil |

| Cutterbar oil check | Combination sight glass, drain plug |

| Number of disks | 10 |

| Number of knives | 20 |

| Disk speed | 2,650 rpm |

| Disk drive | Gear |

| Type | John Deere |

| Angle range | 2-8 degree (angle) |

| Angle adjustment | Manual or hydraulic |

| Adjustable gauge shoes | Yes |

| Cutting height | 1.6-11.7 cm 0.63-6.7 in. |

| Oil reservoir capacity | 11.4 L 12 U.S. qt |

| Knife tip speed | 307 km/h 191 mph |

| Cutting width | 4.9 m 16 ft |

Dimensions

| Standard tires | 31x13.5 15 8PR |

| Transport width | 5.03 m 16.5 ft |

| Transport length | 9.9 m 32.5 ft |

| Weight, roll conditioner | With Urethane roll conditioner: 4,010 kg 8,840 lb With V-10 steel roll conditioner: 4,091 kg 9,020 lb With Tri-Lobe roll conditioner: 4,148 kg 9,145 lb |

Key Specs

| Optional hitch | Drawbar swivel |

| Standard hitch | Rockshaft swivel |

| PTO speed | 1000 rpm |

| Transport width | 5.03 m 16.5 ft |

| Number of disks/knifes | 10 20 |

| Hydraulic pressure required | 17,237 kPa 2,500 psi |

| Cutterbar - cutting width | 4.9 m 16 ft |

| 1000 rpm 1-3/8 in. PTO | 120-210 hp 89-157 kW |

Rolls conditioner

| Speed | 1000 rpm |

| Drive | Telescoping shaft |

| Type of material | Urethane or Steel |

| Design | Urethane: Recessed cleat, Steel Intermeshing flutes (V-10 and Tri-Lobe) |

| Width | 269 cm 105.5 in. |

| Diameter | 25.3 cm 9.96 in. |

Tractor equipment

| Tractor connection | 21 spline |

| Standard hitch | Rockshaft swivel |

| Optional hitch | Drawbar swivel |

| Hydraulic pressure required | 17,237 kPa 2,500 psi |

Additional information

| Date collected | August 24, 2020 |